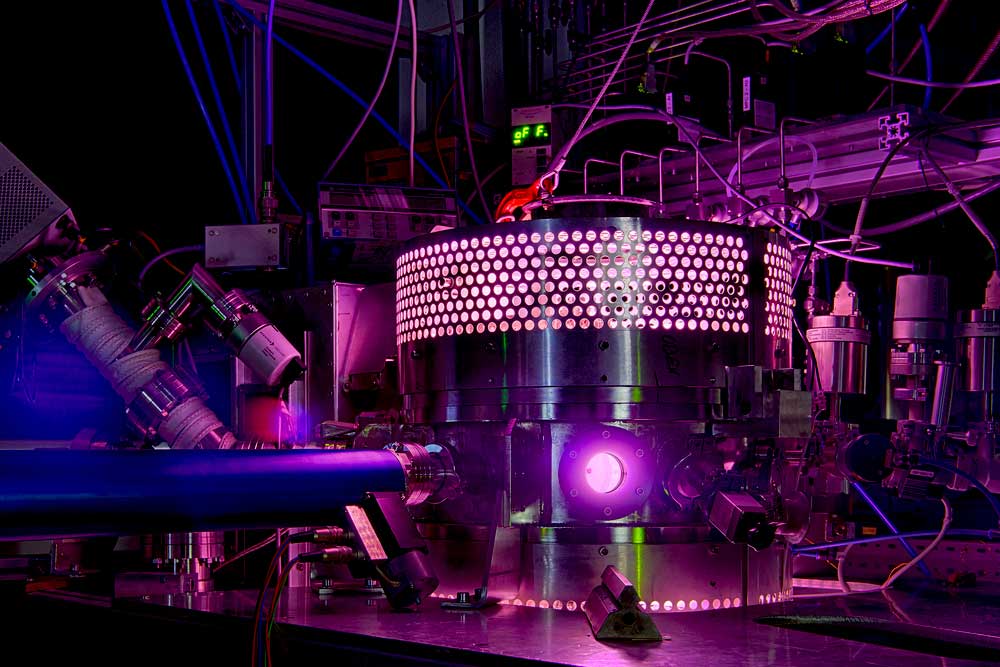

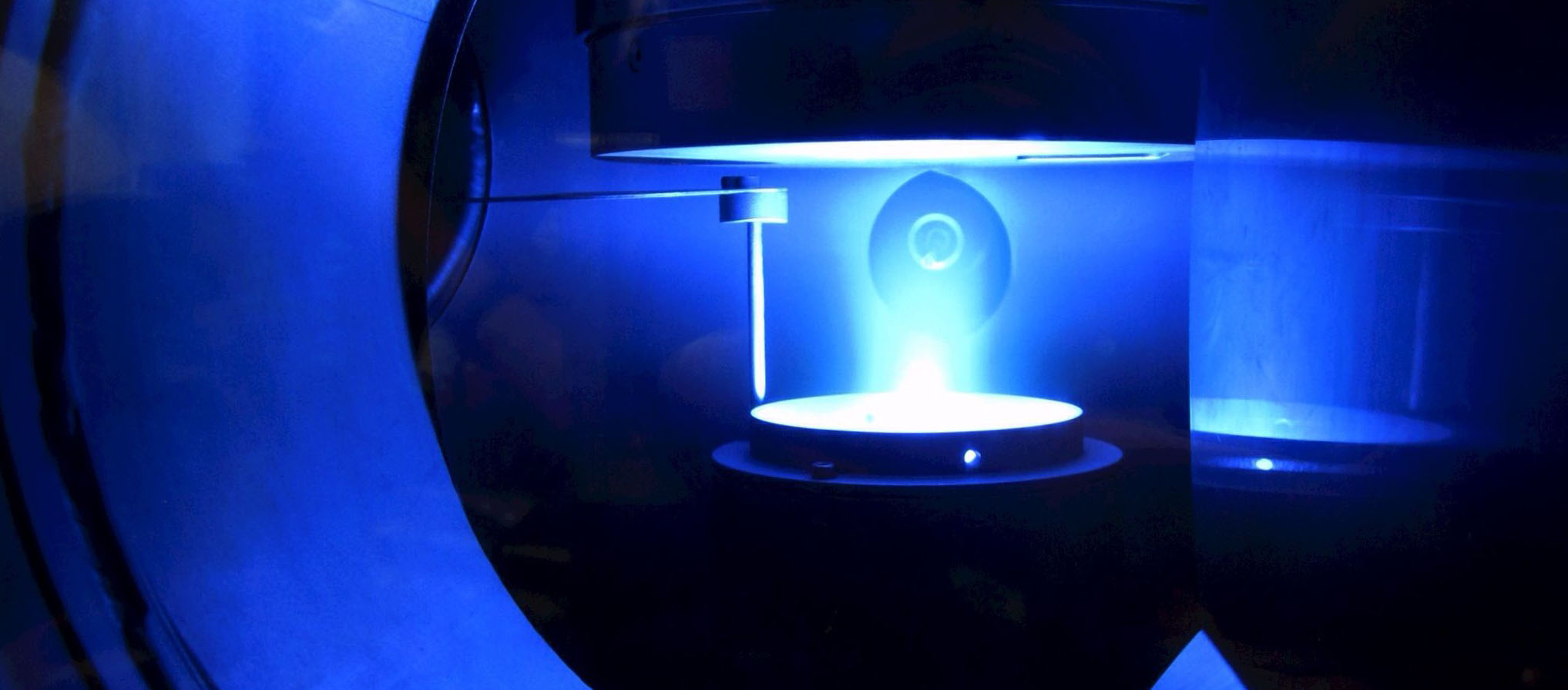

Plasmas facilitate the production of small structures

Martin Hoffmann explains why plasma processes are essential for microsystem technology and which opportunities they offer for eco-friendly manufacturing methods.

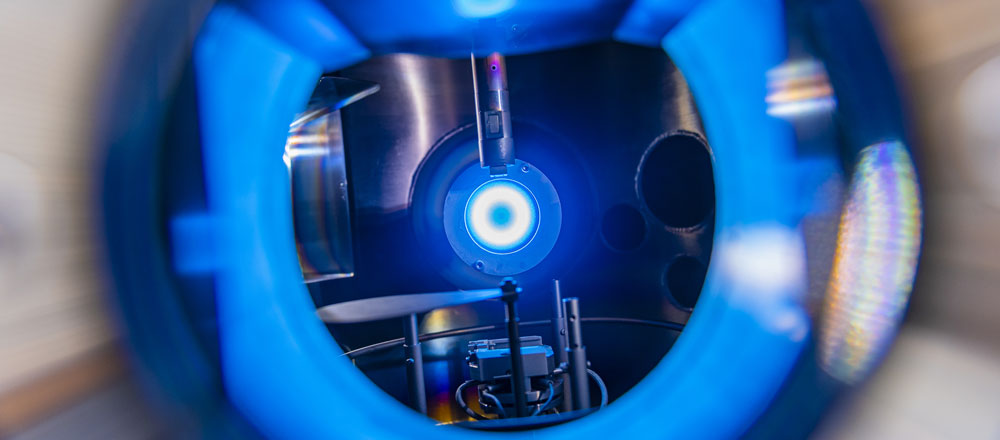

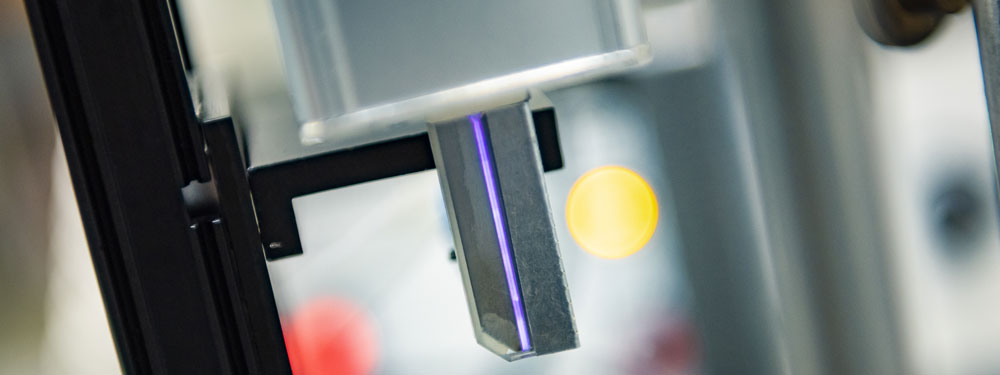

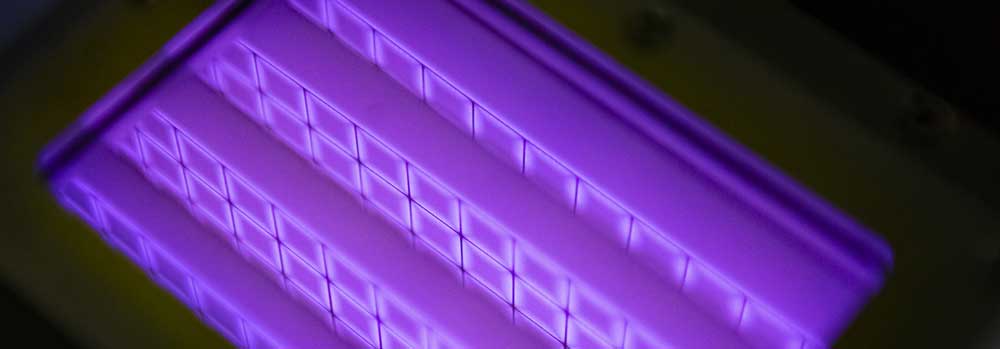

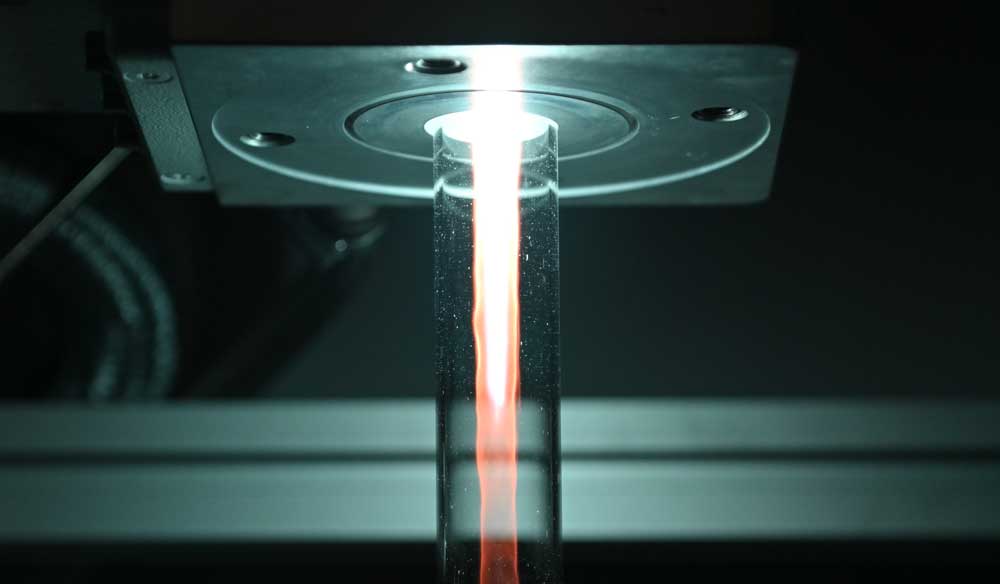

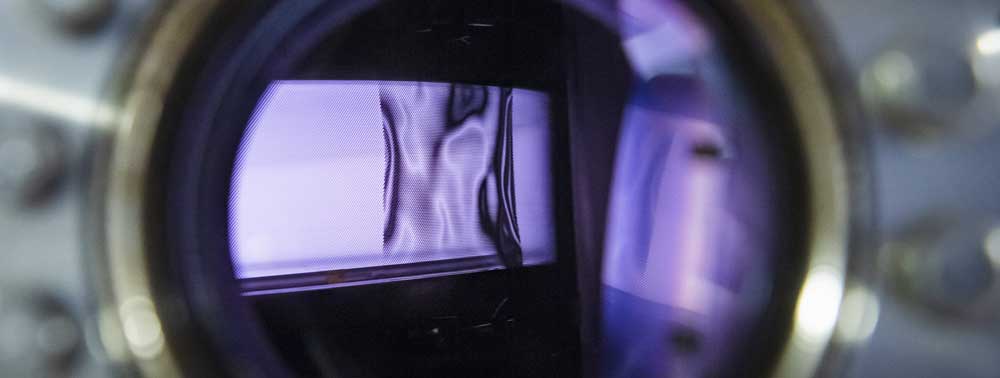

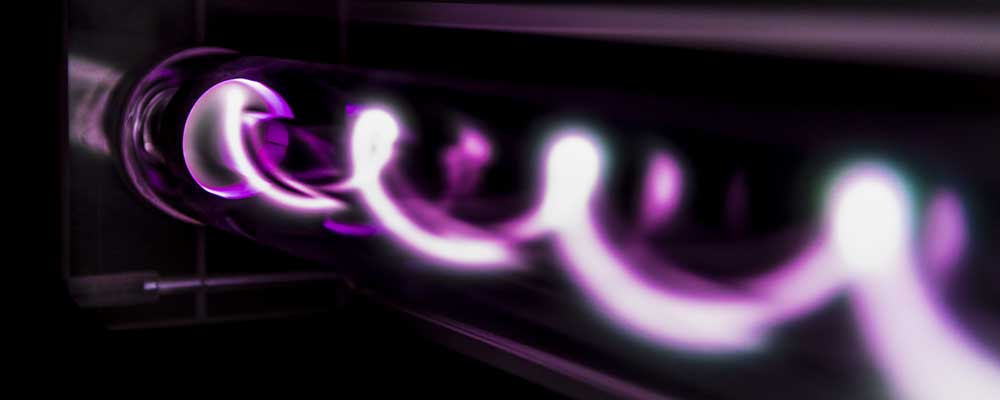

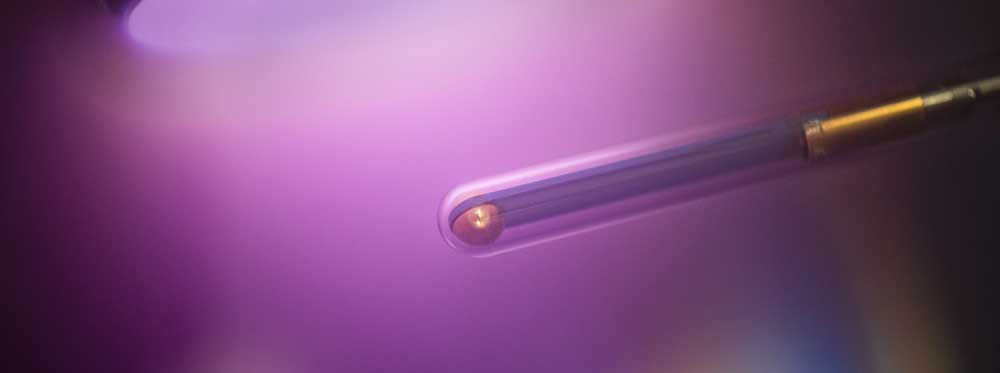

Plasmas are the tool of choice for microsystem technology. As electronic chips are getting smaller and smaller, structures can only be realized with dry, plasma-assisted processes. Wet chemical processes no longer work in these dimensions. During drying, small, movable structures are glued together by surface tension, just as two sheets of glass with a very thin film of water between them can hardly be separated. New materials such as glasses or 2D semiconductors require new processes for deposition and structuring.

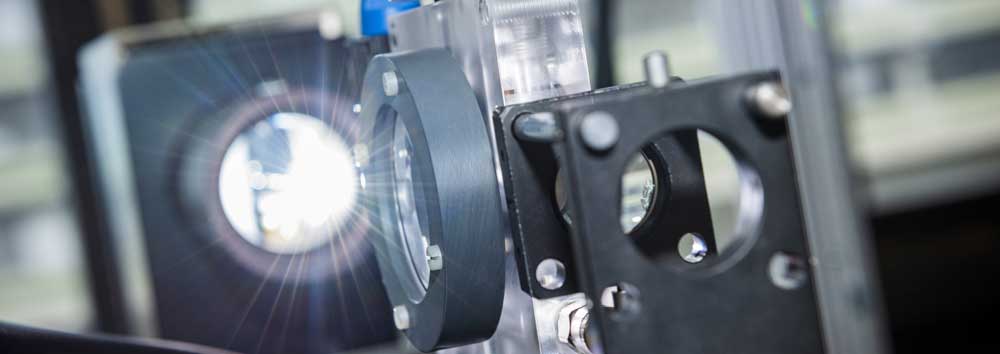

The key is specially adapted plasmas. In addition, we need to significantly advance the methods for measuring the internal parameters of a plasma and the relevant process control in real time. This is the only way we can also achieve reproducible results in batch production. In addition, plasma processes offer resource-saving, environmentally friendly manufacturing methods with minimal material input – even when coating with new types of materials. This future begins now, with the construction of research facilities at the boundary between basic and applied research and cross-disciplinary cooperation to enable the use of innovative materials.