2019 - ongoing

Electron heating in capacitive RF plasmas based on moments of the Boltzmann equation: From fundamental understanding to knowledge-based process control

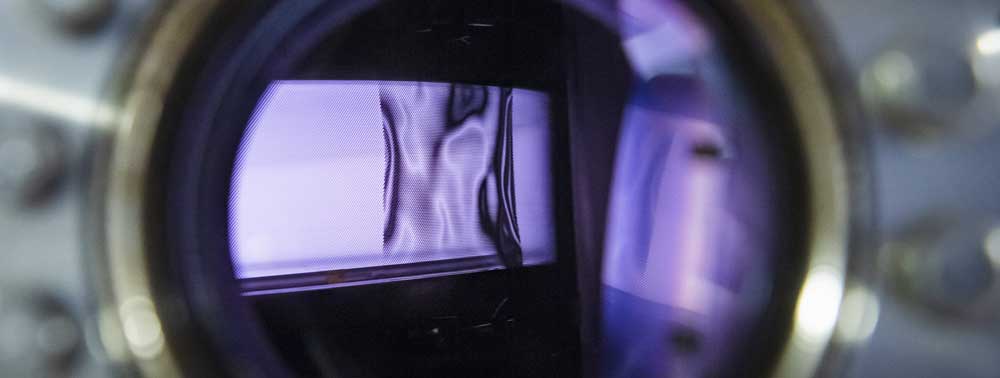

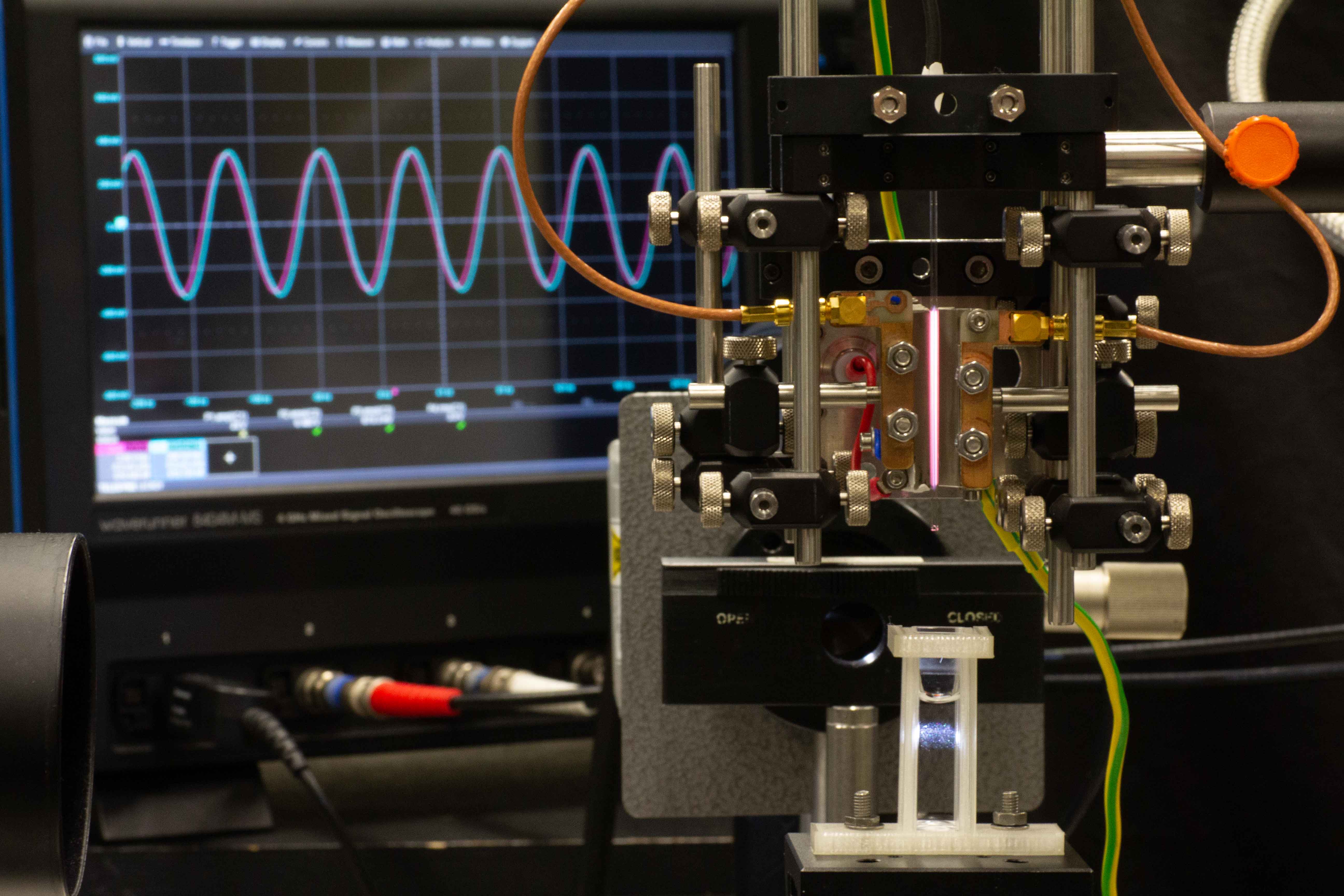

Capacitively coupled radio frequency low temperature plasmas (CCP) are frequently used for a variety of applications of high societal relevance ranging from etching and deposition processes on microscopic scales to biomedical applications in wound healing and cancer therapy. However, the fundamentals of their generation, i.e. the space and time resolved electron power absorption dynamics, are not understood. These dynamics determines the ionization and dissociation of the neutral gas as well as the formation of process relevant energy distribution functions of different particle species. Consequently, plasma processes are typically optimized empirically and not based on scientific understanding. This results in strong limitations of process control.Various theories to describe the electron power absorption exist, but they are mostly based on strong simplifications of the first velocity moment of the Boltzmann equation. This includes the negligence of electron inertia, pressure gradients, the assumption of a homogeneous and harmonic electric field in the plasma bulk, and a simplified treatment of collisions. The classical concepts of ohmic and stochastic electron heating are a result of these simplifications.

Recent works have demonstrated that these assumptions are highly questionable and incorrect under a variety of process relevant discharge conditions. It was shown that these models result in a fundamentally incorrect understanding of CCP operation and, thus, do not allow to realize a knowledge based optimization of plasma processes. Instead a spatio-temporal analysis of the complete first moment of the Boltzmann equation based on input parameters from Particle in Cell simulations must be performed. This approach was demonstrated to provide a complete space and time resolved understanding in a single frequency low pressure CCP operated in argon.

In this project, this so-called Boltzmann term method will be applied systematically to CCPs operated under process relevant conditions to obtain a fundamental understanding of the electron power absorption dynamics with high spatial and temporal resolution within the radio frequency period. Single- and multi-frequency CCPs (including Tailored Voltage Waveforms) operated in electropositive and -negative gases as well as reactive gas mixtures and at pressures ranging 0.5 Pa to atmospheric pressure will be studied as a function of the fundamental driving frequency. The theoretical/computational results will be compared to experiments. The role of different heating mechanisms and their effects on the formation of electron energy distribution functions (EEDF) will be clarified. Based on these fundamental insights concepts to control the EEDF will be developed. Finally, the existing theoretical concepts to describe the plasma conductivity and permittivity as well as the collision operator, which are also a result of these classical assumptions, will be revisited and replaced by more accurate expressions.

The project is funded by the German Research Foundation. Project leader is Dr. habil. Julian Schulze.

2019 - 2022

Me2H2

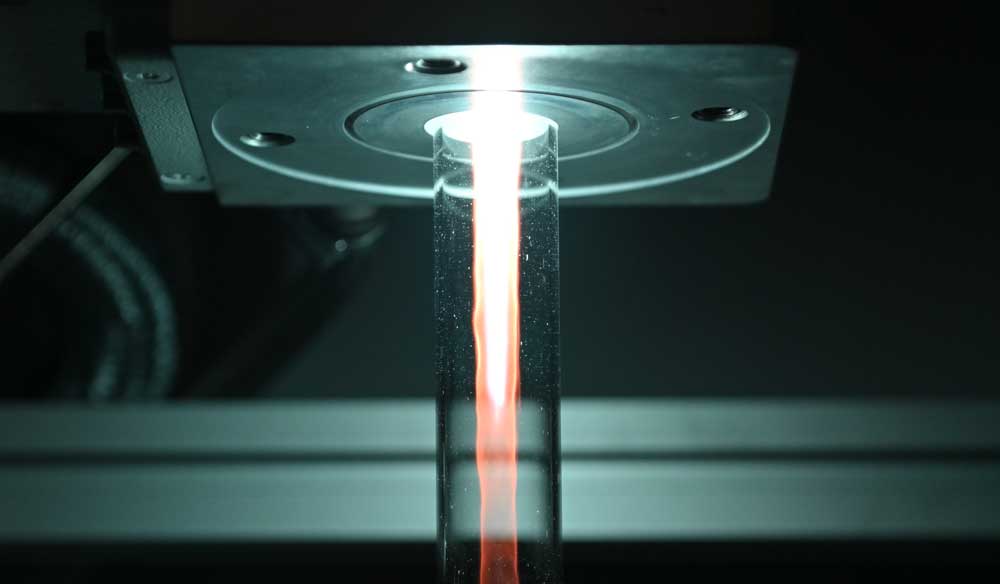

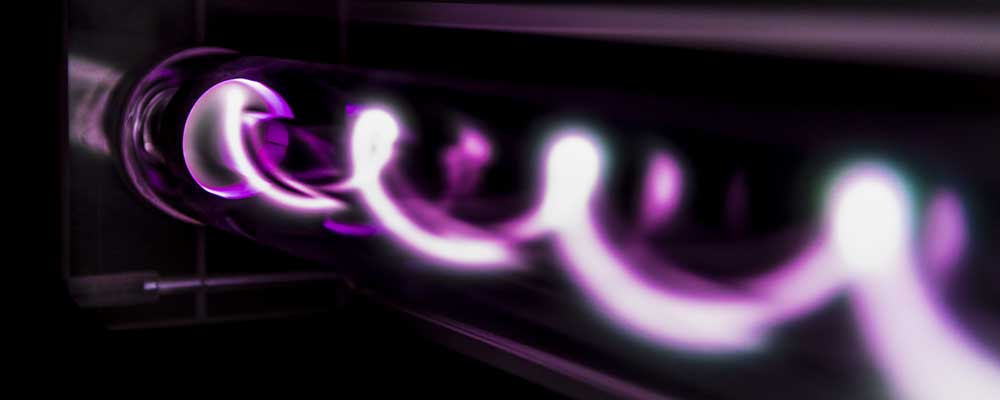

The project Me2H2 aims at the development of processes for a climate-friendly production of hydrogen with minimal power consumption. Water electrolysis is the benchmark for future H2 production without direct CO2 emissions. If operated with renewable electricity, H2 generation would also be climate-friendly with regard to upstream electricity generation. However, water electrolysis specifically consumes significantly more energy than today's industrial benchmark - the steam reforming of natural gas. Methane pyrolysis, on the other hand, would operate CO2 free with a similarly low specific energy requirement as steam reforming. In project U2, plasma-heated processes for methane pyrolysis on a laboratory scale are under investigation.

Contact Persons

Simon Kreuznacht

Ruhr-Universität Bochum

Institute of Experimental Physics II

Faculty for Physics and Astronomy

Universitätsstraße 150

Building NB 5/72, D-44780 Bochum

Phone: +49 (0)234 32 27095

Fax: +49 (0)234 32 14171

Prof. A. von Keudell

Ruhr-Universität Bochum

Institute of Experimental Physics II

Faculty for Physics and Astronomy

Universitätsstraße 150

Building NB 5/125, D-44780 Bochum

Phone: +49 (0)234 32 23680

Fax: +49 (0)234 32 14171

Funding

The project is founded by the Federal Ministry of Education and Research (BMBF), project Me2H2 , project U2

2018 - 2021

CAP-TBC

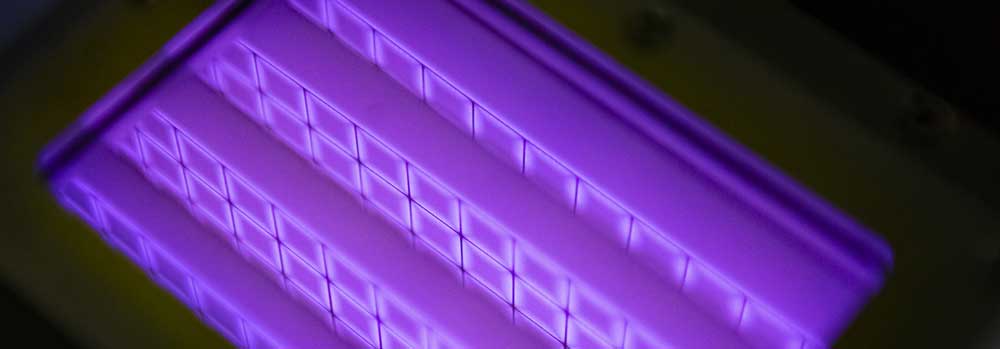

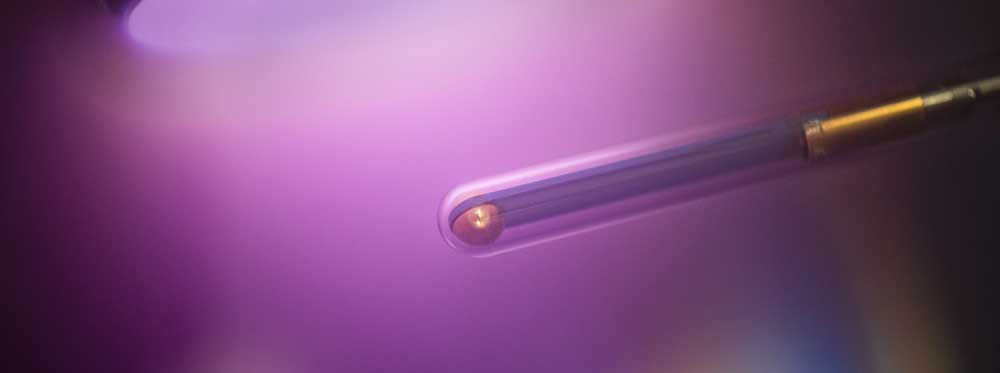

Mold temperature control and optimum parameterization of the process play a key role in the production of high-quality injection molded components. Inadequate temperature control of the mold walls can often result in surface defects such as gloss differences or weld line notches during the injection molding of molded parts. However, the use of dynamic temperature control techniques to minimize surface defects leads to significantly lower cost effectiveness, due to the additional energy added and the resulting longer cooling phase. The use of thermal barrier coatings slightly slows down the cooling process of the mold filling compound and thus makes extremely efficient use of the heat introduced into the plastic during the melting process. This makes it possible to increase the energy efficiency of the injection molding process without compromising part quality. Due to their low thermal conductivity and adapted coefficients of thermal expansion, oxide ceramic materials such as zirconia are the ideal materials for passive insulation layers. Within the scope of this project, innovative thermal insulation coatings and coating processes for injection molds are to be developed in an international project consortium. Significant improvements are to be made with regard to the achievable growth rates of the coatings

(>500 nm/h) as well as a reduction of the necessary layer thicknesses (<30 μm).

For this purpose, the application of functional coatings by metal organic chemical vapor deposition (MOCVD) is to be combined with plasma activation of the precursors. In this way, the advantages of conformal MOCVD layer formation with increased reactivity at low process temperatures, shorter process times and optimized porosity are to be achieved. With the envisaged development goals, effective process control and reproducible application of the coatings would be feasible for an industrial environment.

More information:

Kunststoffinstitut Lüdenscheid

Project leader

Prof. Dr. Achim von Keudell

Experimental Physics II

Ruhr-Universität Bochum

Universitätsstraße 150

NB 5/125, 44801 Bochum

2018-2023

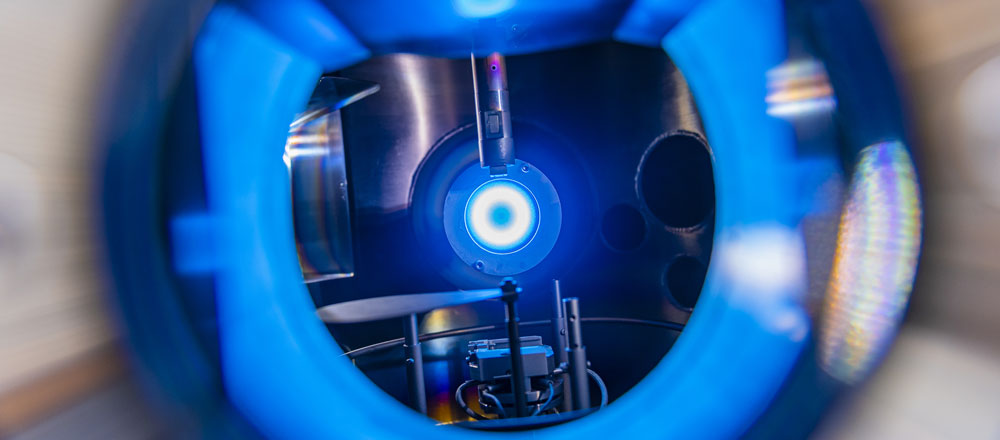

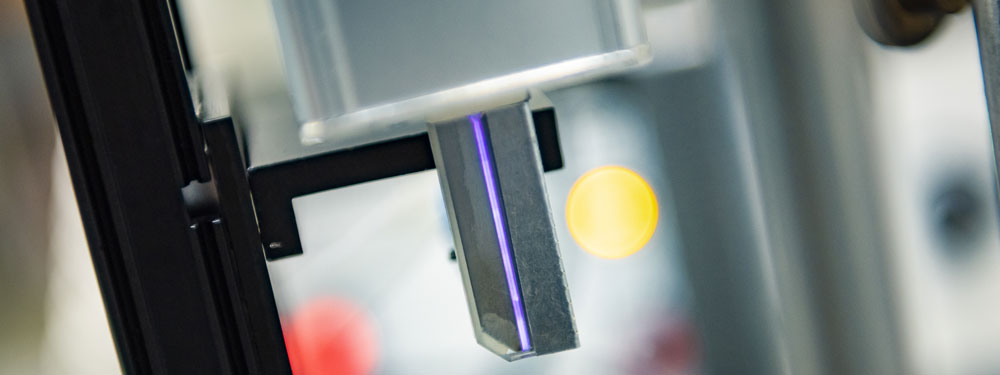

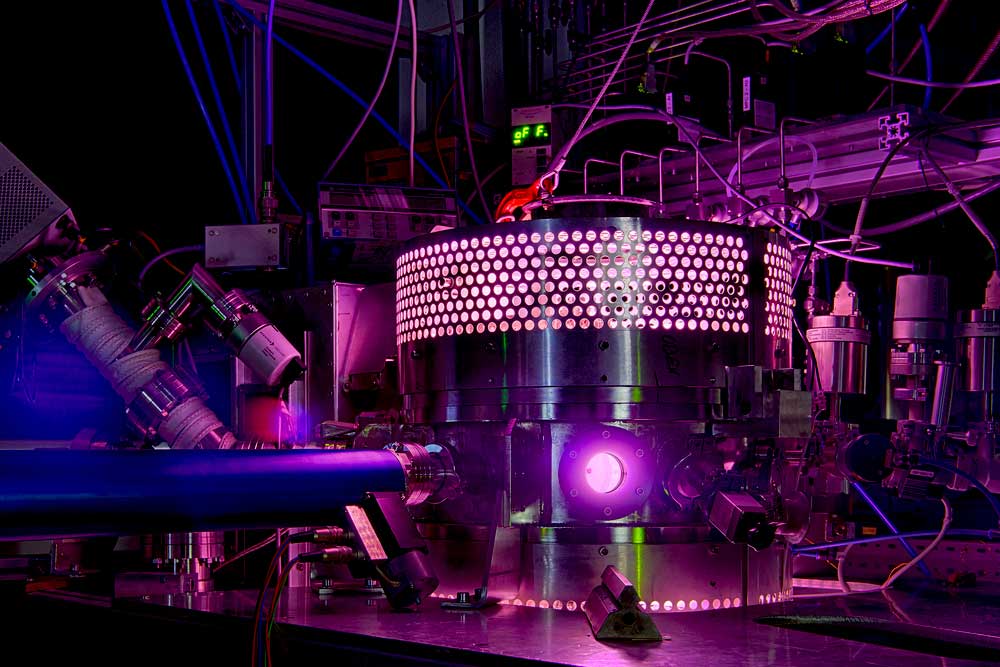

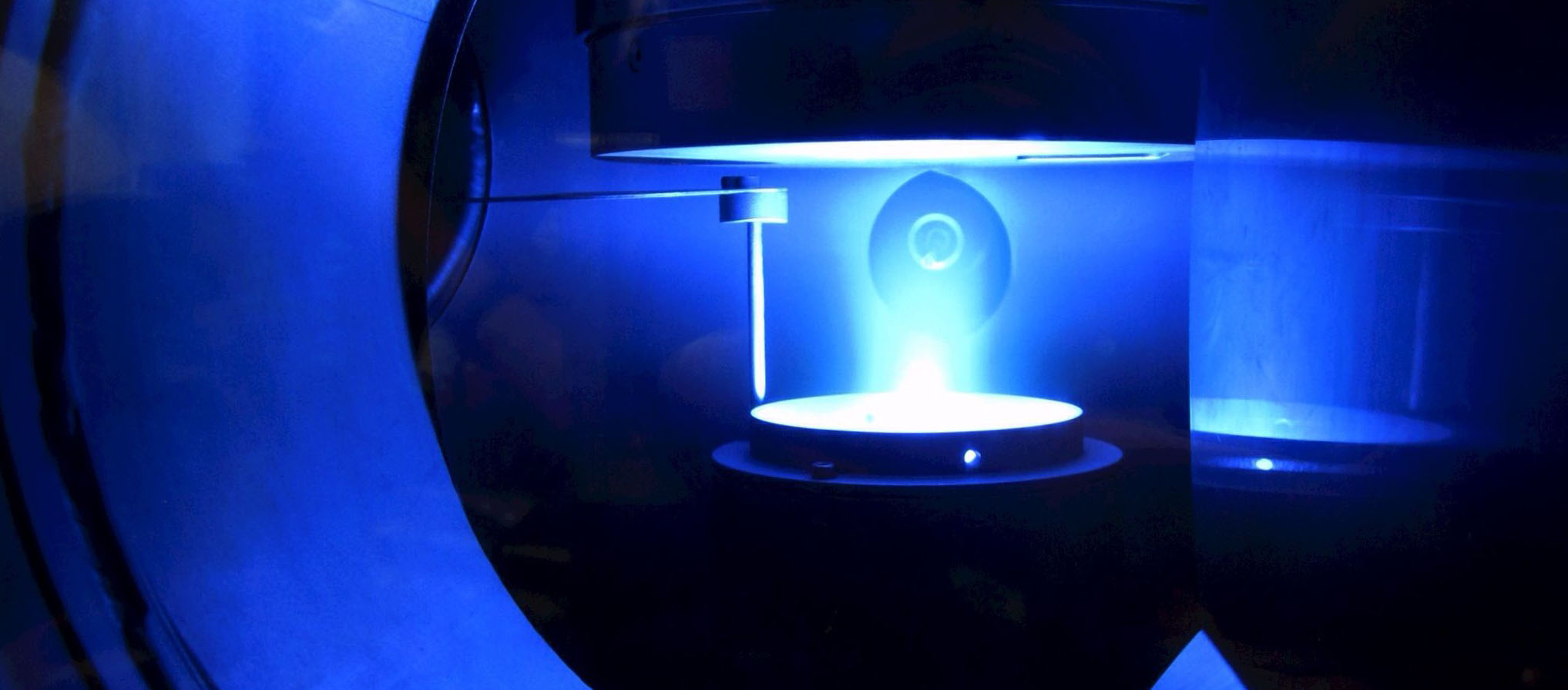

Plasma-based process control of reactive sputtering processes

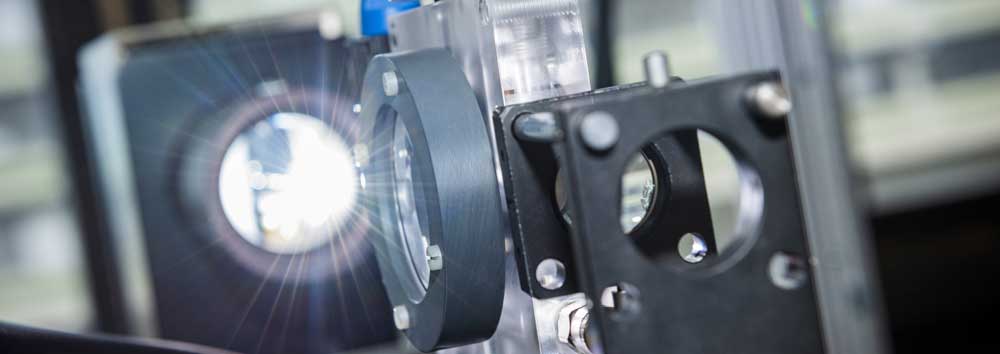

Reactive sputtering processes in low-temperature plasmas are used for the deposition of thin films as the basis for many high-tech products. Despite this enormous social importance, fundamental mechanisms such as electron heating, plasma surface interactions and transport phenomena in these plasmas are not understood. Consequently, the non-linear and non-local influences of global parameters such as neutral gas pressure, gas flows, power, magnetic fields, etc. on the properties of the deposited thin films are not understood. This leads to massive limitations in process optimization and control. Lack of understanding and access to the actual layer-determining distribution functions of different species at the surfaces as well as the properties of these interfaces, existing process controls are based on the control of secondary variables such as gas flows and powers, which do not clearly determine the layer properties, as well as greybox models.

Thus, sputtering processes are representative for a multitude of plasma processes where similar problems exist. In this project, a plasma-based process control of reactive sputtering processes for the deposition of Al2O3 layers in a capacitive radio frequency (RF) magnetron, i.e. based on plasma sizes and scientific understanding, will be developed and tested for the first time. The first goal is to develop a fundamental understanding of the effect of global control variables on layer-determining distribution functions, surface and layer properties. For this purpose, a synergistic combination of experimental and theoretical methods will be used by characterizing the discharge numerically by a variety of plasma and surface diagnostics experimentally as well as by kinetic simulations. Based on this fundamental understanding, plasma quantities suitable for process control are to be determined, which can be measured non-invasively within seconds during the process and clearly correlate with the layer-determining distribution functions and surface properties.

These quantities are to be described by fast reduced global models, which make predictions about the causes and compensation measures of unwanted process drifts. The measured plasma quantities and models will then be used in a parallel developed control loop for process control, based on which a significantly improved control of thin film properties will be demonstrated. The aim is to make plasma properties such as the energy per incorporated particle adjustable in order to correlate the layer properties with the plasma properties and thus to be able to control layer properties. If successful, this concept of plasma-based process control can be transferred to other processes. In addition, important fundamental insights into the plasma physics of such discharges are expected.

The project is funding by the German Research Foundation (2018-2023). Project leaders are Prof. Brinkmann, Dr. habil. Julian Schulze, and Prof. Lunze from Ruhr-University Bochum.

2016 - 2024

Carbon2Chem

The BMBF project consists of 17 partners from industry and science with the goal to reduce the emission of carbon dioxide.

In detail, the use of gases from metallurgical plants are used for the production of chemicals, so that the emission of carbon dioxide is sustainably reduced. The requested hydrogen for this process is produced with the help of renewable enegry sources. The aim of CO2 reduction in the Ruhr area as well as at other metallurgical plants should be used in an economical way.

The project started at June 1st, 2016 and lasts until May 30th, 2024.

Further information

Spokesperson for Ruhr-Universität Bochum

Prof. Dr. Martin Muhler

Industrial Redox Catalysis

Ruhr-Universität Bochum

Universitätsstraße 150

44801 Bochum

Tel.: +49 (0) 234 - 32 28754

Fax: +49 (0) 234 - 32 14115

2015 - 2018

Astrophysical Processes in the Heliospheric Environment

The BMBF promoted project "Astrophysical Processes in the Heliospheric Environment" is coordinated by the Ruhr-Universität Bochum. Project partners are Rheinische Friedrich-Wilhelms-Universität Bonn, Christian-Albrechts-Universität zu Kiel, Julius-Maximilians-Universität Würzburg as well as the Max-Planck-Institut für Sonnensystemforschung in Göttingen.

The transit time is from April 1st, 2015 up to March 31st, 2018.

Abstract: To enhance the understanding of the heliosphere and her surrounding as astrophysical system, the project includes the development, expansion, and refinement of theory and modelling of turbular (inter)stellar plasmas and the transport of energetic partlices in it.

Contact

PD Dr. Horst Fichtner

Ruhr-Universität Bochum

Theoretical Physics IV - Heliophysics

Universitätsstr. 150

NB 7/26, 44801Bochum

2014 - 2018

Project Pluto+

The network project PluTO+ aims to increase the quality and yield of optical deposition technologies started in Octobre 2014. It has an overall volume of 9.5 billion Euro. The BMBF supports the project within the support programme "Photonik Forschung Deutschland". Project coordinator is Bühler Alzenau GmbH, more information can be found here.

Contact

Prof. Dr. Ralf Peter Brinkmann

Chair for Theoretical Electrical Engineering

Ruhr-Universität Bochum

Universitätsstr. 150

ID 1/127, 44801 Bochum