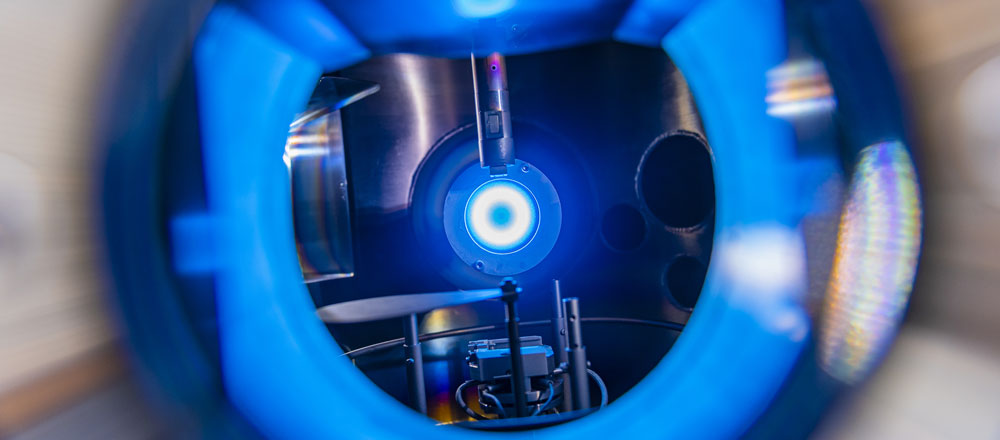

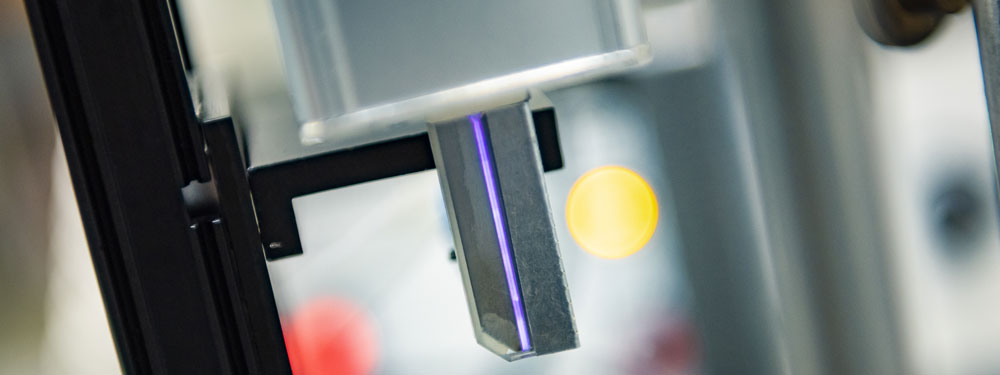

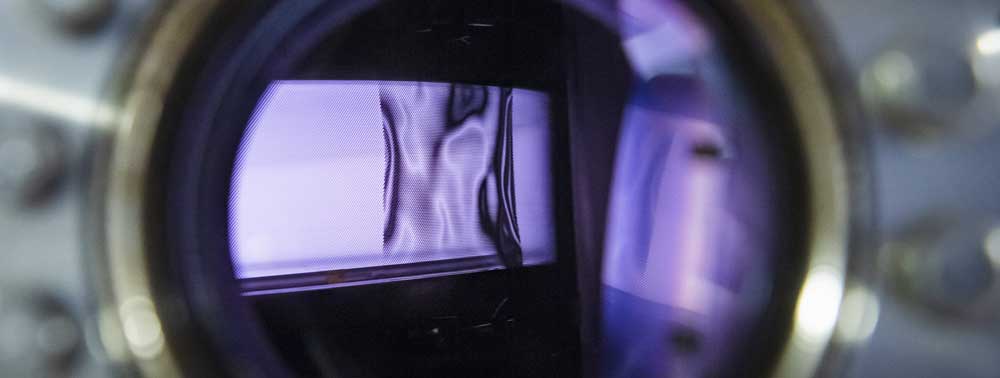

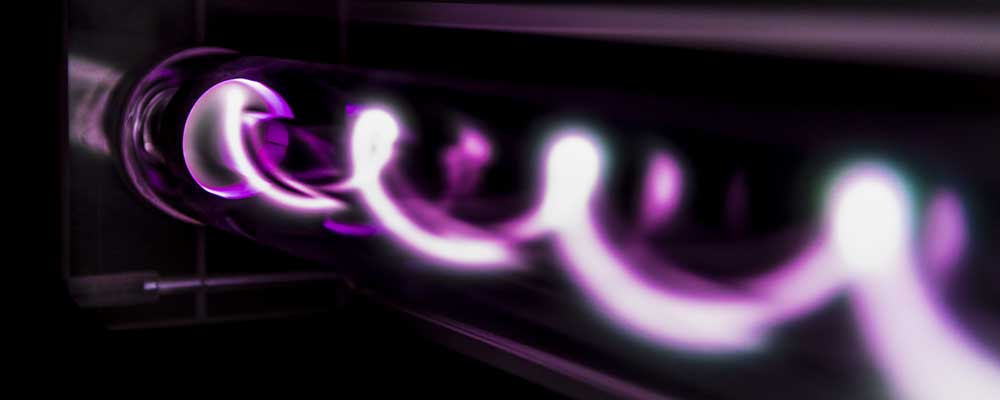

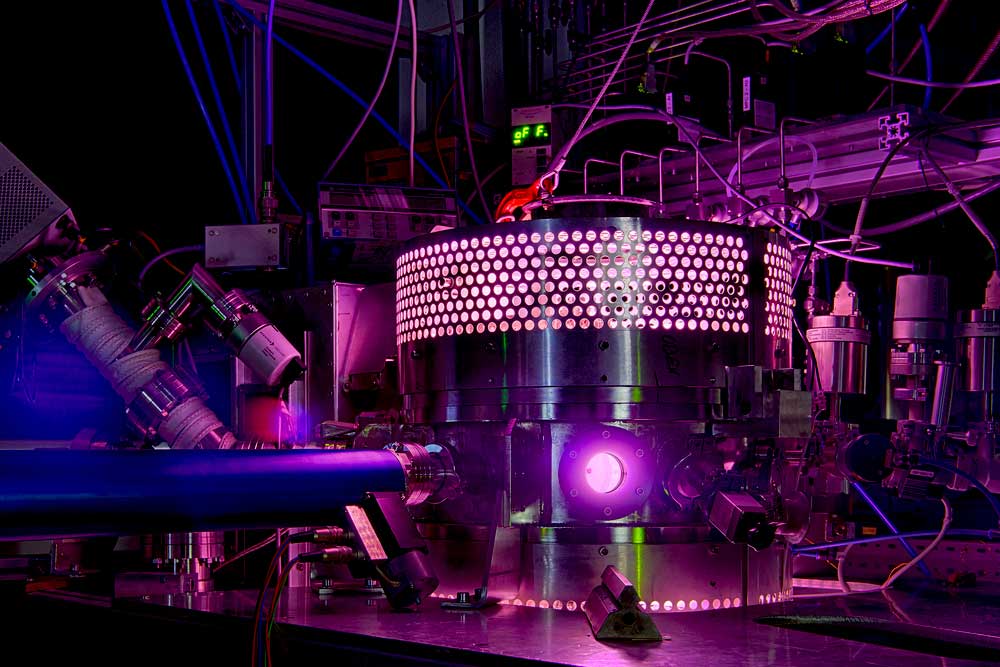

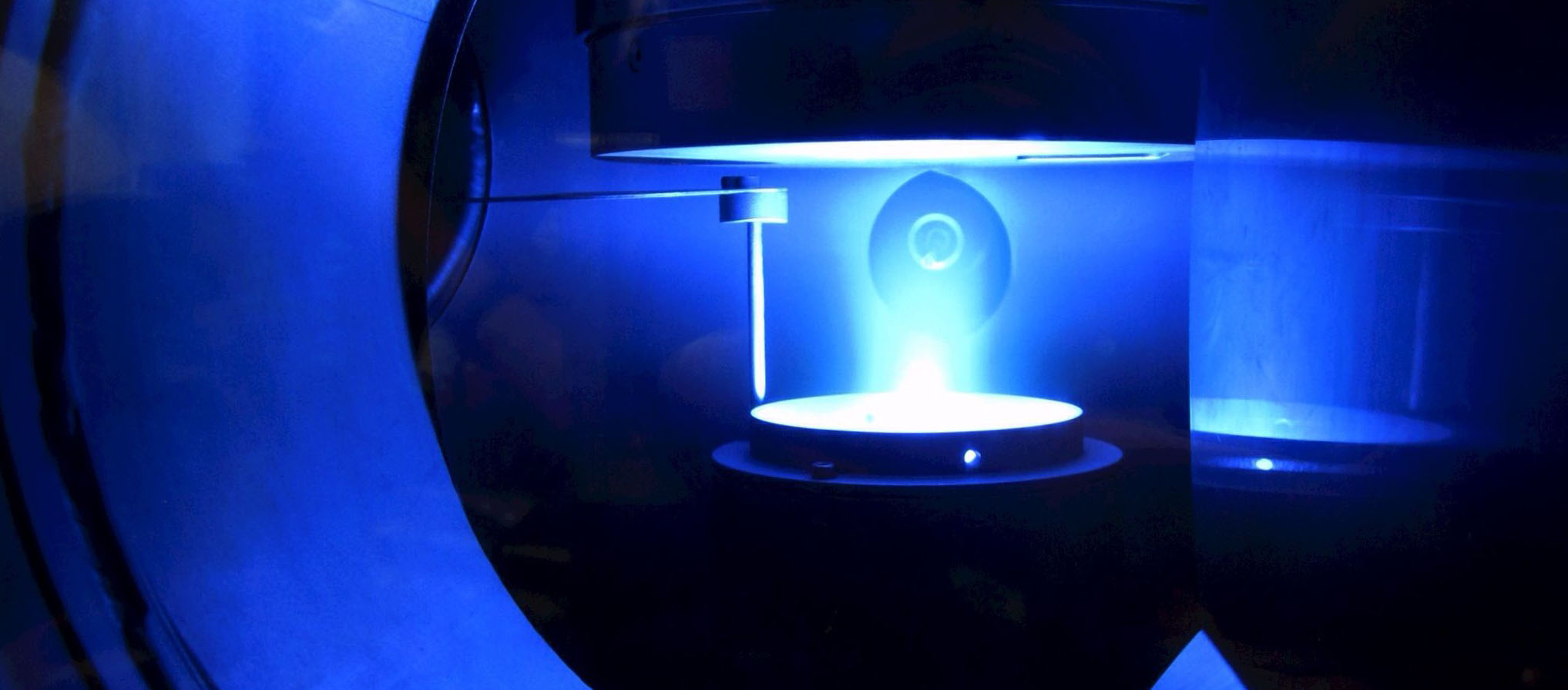

Live monitoring of the inner plasma process

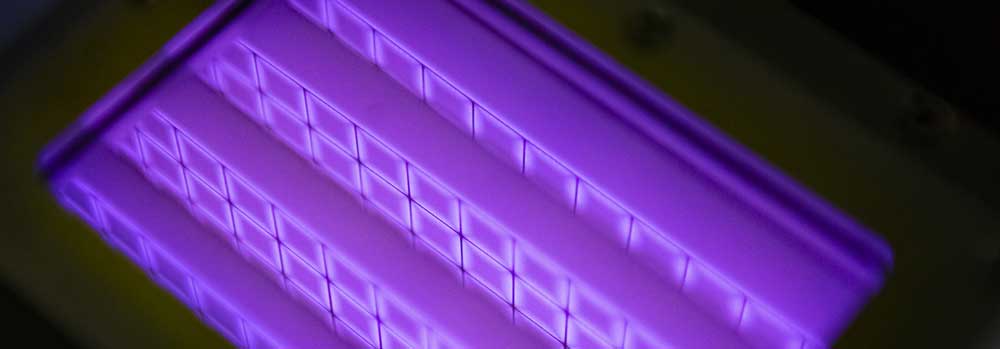

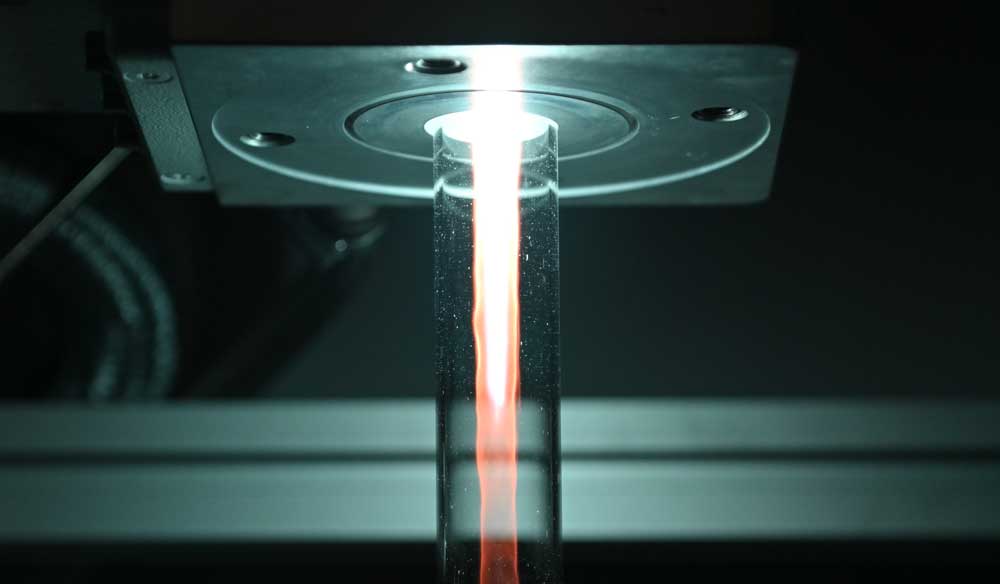

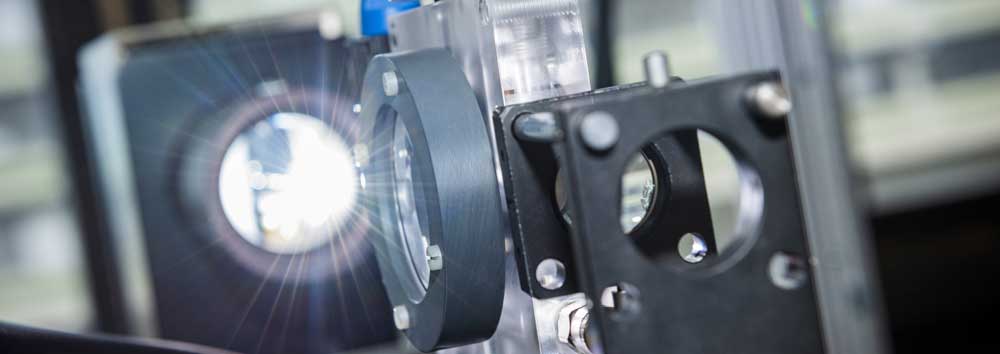

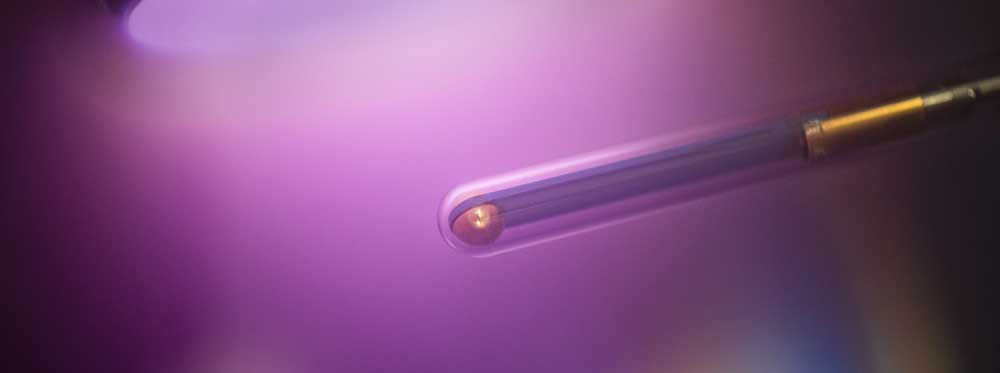

Dr. Moritz Oberberg and two team colleagues are preparing to set up the spin-off “House of Plasma”. The company is launching the Multipole Resonance Probe in various designs. It allows industrial plasmas to be monitored in real time to ensure that they help to consistently apply identical, faultless coatings to surfaces, for example.

Mr. Oberberg, if someone had told you five years ago that you would plan to start a company today, what would you have said?

The idea of setting up a spin-off with measurement technology is not that new. My predecessor, who completed his doctorate in 2015, was already talking about it, but it wasn’t fully developed at the time. Personally, I could always picture myself being self-employed. The timing depends, of course, on the development and the response. Still, I’ve been thinking about self-employment for a while. I have a background in this field and, in addition to my education, I also have the necessary contacts.

The company has not been established yet. How do you keep busy at the moment?

Well, I’m not alone, the three of us share all tasks that come up. We are currently planning industrial tests with a company for our latest designs – we have to travel abroad for this purpose. There’s a lot of red tape. It’s not so easy to take measuring equipment out of the country.

Other than that, I’m busy pushing the development of our products and writing project proposals. I should mention that RUB offers invaluable support with the Worldfactory Startup Center. It has a team of excellent people who help us with everything. At the moment, for example, we are working out how to acquire patents held by RUB. Articles of incorporation are still to be written before we can set up the company, the financial plan is being finalised, and the search for investors is also underway. Before we can sell something, we have to be able to purchase, for which we need capital; the same is true for marketing, premises, equipment and so on. In the current funding project at the university, tests continue in the laboratory and with industrial partners, under difficult conditions due to the pandemic, and the technology is constantly being optimised. This is all going on simultaneously.

What can prospective customers expect from you?

Our prospective clientele might include, for example, a company that coats spectacle lenses. We would check with them what their expectations are and whether our technology offers added value for their company. Can it be used? If yes, then our hardware in combination with the relevant software can provide insights that were not there before.

We compare it to a breakfast egg: I like it when the yolk is still soft but the egg white is hard. However, while it’s cooking, I can only rely on my experience, not really measure what’s going on inside the egg. At most, a peripheral measurement of the temperature on the shell would be possible, but not inside the egg. What we do now, however, is supply the data straight from the egg.

adapted from Meike Drießen (RUB)