FOR 1123: Physics of Microplasmas

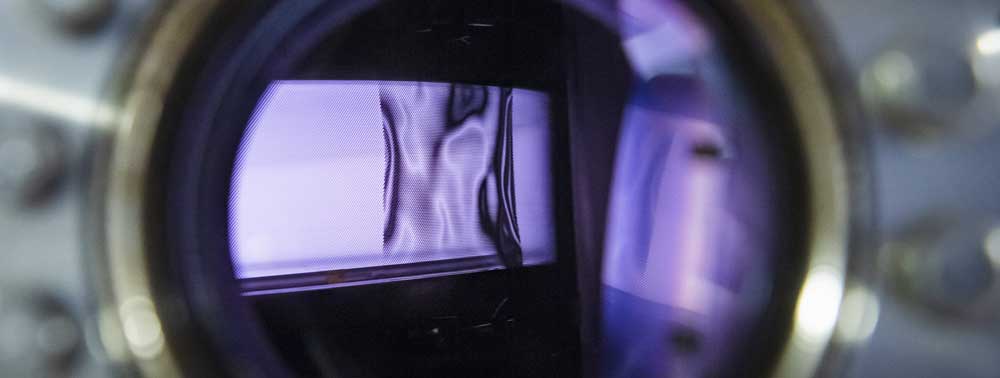

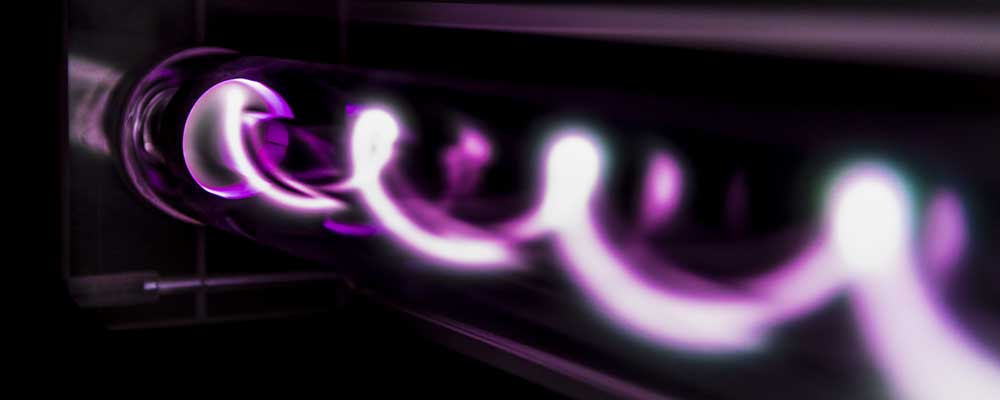

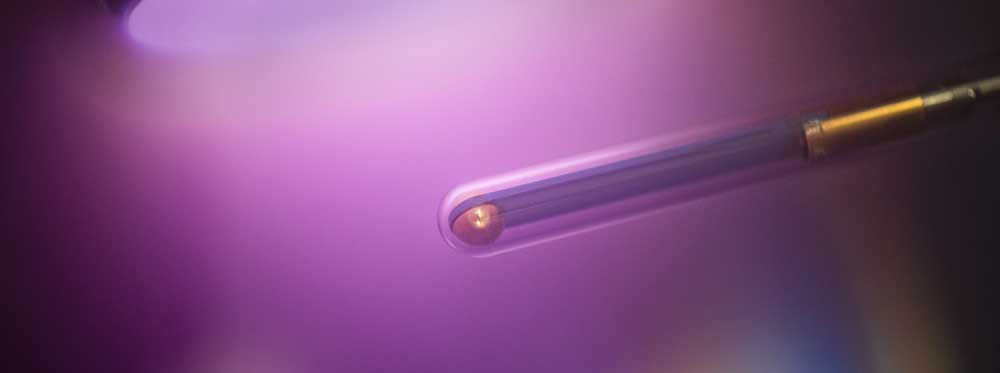

Microplasmas have gained very high attention recently. They are operated at around atmospheric pressure in small volumes with a scale length of typically 100 µm. They are thus highly collisional.

Still, due to the confinement in narrow space, microplasmas have pronounced non-equilibrium properties with hot electrons but cold gas temperature. They are most useful for a variety of applications. Though the absolute power may be small their power density is enormous. They are characterised by high electron densities and very high electric fields close to the surface. The Debye length contracts below 1 µm, the mean free paths of species become very small and the classical separation between bulk and sheath disappears. Microplasmas can have extreme properties.

Subject of this Research Unit is a systematic investigation of selected microdischarge configurations in order to better understand their complex dynamics from breakdown to full evolution of the discharge, understand the space- and time dependent transport of energy, radiation and reactive species, and the plasma surface interactions under these extreme conditions. Finally, we investigate prototypical applications of microplasmas.

The key physics questions we want to address are:

- understanding the space- and time dependent energy coupling, energy flow, radiation, transport and the reactive particle balance inside and outside of the microdischarge

- understanding the discharge dynamics from ignition to discharge evolution during rf-phases

- understanding what governs their stability

- understanding and controlling plasma surface interactions of microdischarges.

Within this Research Unit we will address the following work packages:

- investigation of the discharge breakdown and of the control and modification of plasma surface interactions with its implications on discharge properties using intense photon fields

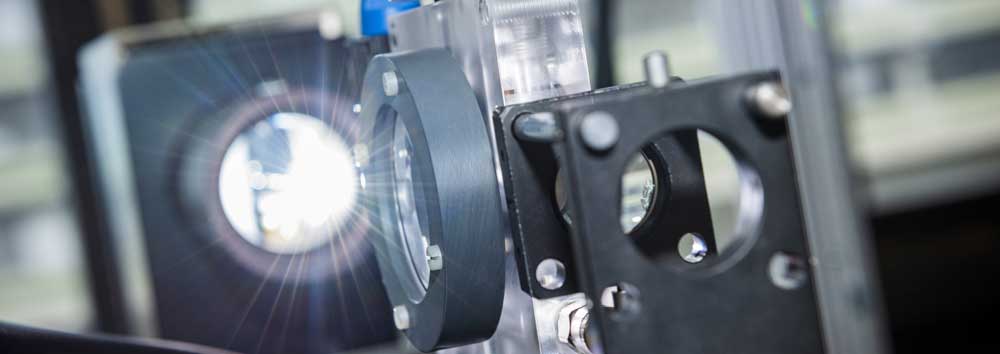

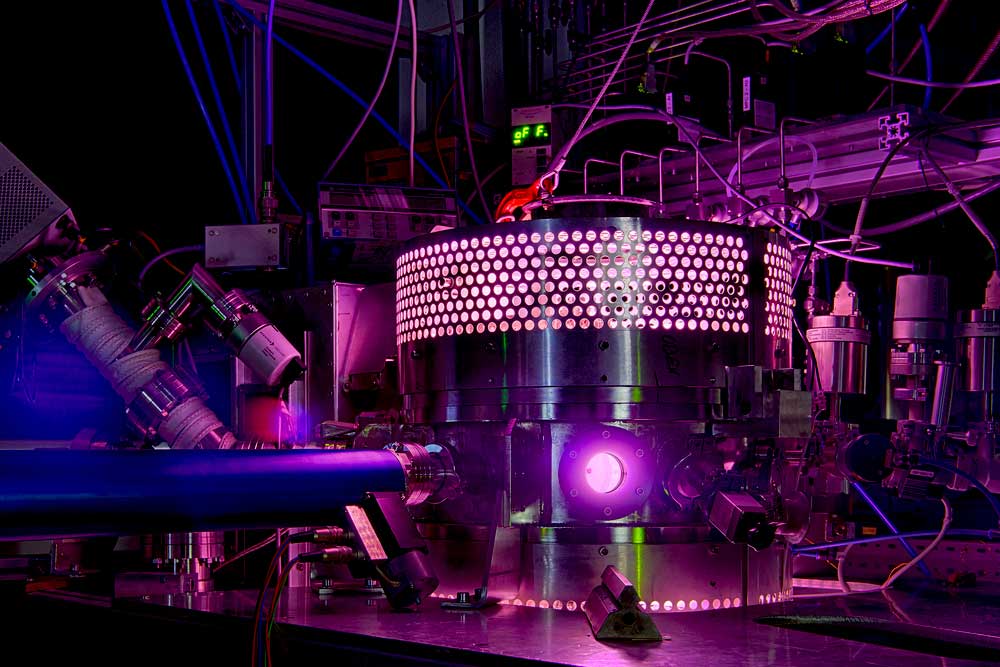

- diagnostics of microplasmas with cutting edge, partly unique techniques such as phase resolved optical emission spectroscopy, multi-photon laser based spectroscopy using nanosecond lasers, broadband absorption spectroscopy employing femto second lasers, Thomson scattering and CARS-type measurements and molecular beam mass spectrometry

- modelling of microdischarges focussing on non-linear sheath phenomena and on "global" approaches as well as the treatment of the kinetics by PIC methods in very close connection to experiments

- exploration of two selected applications of microplasmas in areas with particularly high potential based on the improved understanding of the complex discharge mechanisms.

Projects

- Spectroscopic investigations of transient processes in self-pulsing microdischarges (Applicant Schulz-von der Gathen, Volker)

- Investigation of transient phenomena in microplasmas by absorption spectroscopy and by laser-assisted "pump-probe"-experiments (Applicant Böke, Marc)

- Laser spectroscopic determination of electric fields, electron densities, and electron temperatures in atmospheric pressure microdischarges (Applicant Czarnetzki, Uwe)

- Breakdown, stability and similarity laws of microplasmas (Applicant Stefanovic, Ilija)

- Numerical simulation of microplasma jets and their interaction with surfaces (Applicant Mussenbrock, Thomas)

- Spatial and temporal structures in microplasmas (Applicant Brinkmann, Ralf-Peter)

- Reaction chemistry in reactive microplasma jets (Applicant Benedikt, Ph.D., Jan)

- Investigation of atmospheric pressure filamentary discharges and its application for film deposition on inner surface of tubes, cavities and flat surfaces (Applicant Awakowicz, Peter)

- Central tasks of the Research Unit (Applicant von Keudell, Achim)

Spokesperson

Professor Dr. Achim von Keudell

Ruhr-Universität Bochum

Fakultät für Physik und Astronomie

Institut für Experimentalphysik II

Arbeitsgruppe Reaktive Plasmen

Universitätsstraße 150

44801 Bochum

Telephone: +49 234 3223680

Fax: +49 234 3214171

E-Mail:

Deputy spokesperson

Professor Dr. Jörg Winter

Ruhr-Universität Bochum

Fakultät für Physik und Astronomie

Institut für Experimentalphysik II

Arbeitsgruppe Reaktive Plasmen

Universitätsstraße 150

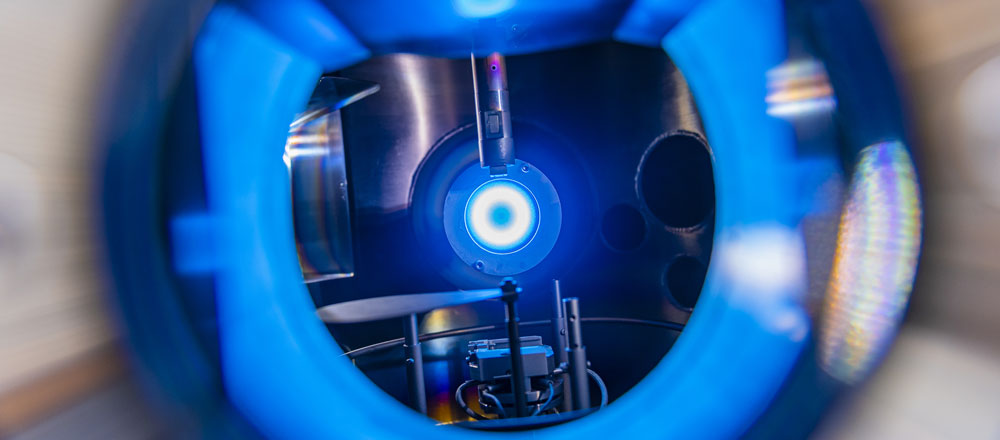

SFB-TR 87: Pulsed high power plasmas for the synthesis of nanostructured functional layers

Research Goal

Structure widths of 50 nm and less, aspect ratios of 1:100 and more, the groundbreaking successes of Plasmaoberflächentechnik point the way for microelectronics and micro and nanostructure technology. The unique successes of this technology are based not least on new plasma source concepts, without which neither the speed nor the homogeneity and stability of the processes would have been possible. To this day, both the processes and the sources are constantly being further researched and developed, with the success that the storage capacity will become even larger, the mobile phones even smaller and the PCs even more powerful. Decisive for this success is the close integration of plasma diagnostics with process technology, in-situ control of process-relevant parameters and their correlation with the structures achieved.

Today's coating techniques, both cathode sputtering processes and plasma-assisted gas-phase deposition, are similar to the plasma etching processes through new source concepts beflügelt. The common feature of the further development of both techniques is a significant increase in source powers up to the megawatt range as well as a pulsed power supply, which allows a targeted Beeinflussung of the plasma parameters while simultaneously controlling the thermal load of the materials. In this way, the plasmas used continue to be operated towards extreme non-equilibrium in order to deposit new metastable high-performance coatings for tribological applications in mechanical engineering. These coating materials are not only unique in terms of their chemical composition. Their nanostructured structure can also only be produced using the latest methods of plasma technology.

The aim of the SFB-TR 87 is to investigate coating systems with unique tribological properties on metal substrates and barrier properties on plastic substrates by bundling the expertise of two sites in the fields of plasma physics/plasma technology and materials science. For this purpose, the latest, partly self-developed source technology is used and characterized by a very broad spectrum of quantitative, partly newly developed plasma diagnostics, supported by modelling and unique single particle experiments. The aim is also to investigate the relationships between material properties and plasma parameters and to use them for plasma control, layer development and in-situ layer control. In this way, the empirical approach prevailing so far is overcome and a physically and chemically based process understanding is developed.

Further information

- Website SBF TR 87 http://www.sfbtr87.de/

Spokesperson

Prof. Dr.-Ing. Peter Awakowicz

Lehrstuhl für Allgemeine Elektrotechnik und Plasmatechnik

Fakultät für Elektrotechnik und Informationstechnik

Ruhr-Universität Bochum

Universitätsstraße 150

44801 Bochum

Tel.: +49 (0) 234 - 32 22487, 23062 Sekretariat

Fax: +49 (0) 234 - 32 14230

Deputy Spokesperson

Prof. Jochen M. Schneider, Ph.D.

Lehrstuhl für Werkstoffchemie

Fakultät Georessources und Materialtechnik

Rheinisch-Westfälische Technische Hochschule Aachen

Kopernikusstraße 10

52056 Aachen

Tel.: +49 (0) 241 - 80 25 966

Fax: +49 (0) 241 - 80 22 295

RAPID - Reactive Atmospheric Pressure Plasma Processing Education Network - MC-ITN

The goal of the Multi-Partner ITN-RAPID (Reactive Atmospheric Plasma processIng - eDucation network) is the realization of an interdisciplinary training involving the disciplines physics, chemistry and engineering. As a result, RAPID will create the platform for a truly European PhD in plasma technology. The scientific goal is the development of non-equilibrium reactive processes in atmospheric pressure plasmas. Thereby, the great success of low pressure plasmas enabling a multitude of applications ranging from material synthesis, automotive and microelectronics can be repeated. In addition, even more applications become possible due to the easy integration of atmospheric pressure plasmas in current industrial processes. Hot topics such as large area solar cells, barrier coatings to improve the permeation properties of polymers and plasma chemical gas conversion are selected. The research success requires a specific training covering diverse aspects such as modeling and simulation of plasmas and surfaces, diagnostic to validate these models and the implications for industrial scale-up. This will be trained in a coordinated effort involving 10 academic and 10 industrial partners from 8 European countries.

Spokesperson

Prof. Dr. Achim von Keudell

Ruhr-Universität Bochum

Research Group Reactive Plasmas

Institute for Experimental Physics II

Faculty for Physics and Astronomy

Buildung NB 5/125

Universitätsstraße 150

D-44780 Bochum

Email:

Phone: +49 - (0)234 - 32 - 27028

http://reaktiveplasmen.rub.de/

Deputy Spokesperson

Prof. Dr. Anjana Devi

Ruhr-Universität Bochum

Chair II of Inorganic Chemistry

Faculty of Chemistry and Biochemistry

Group Devi - Chemistry of Inorganic Materials

Universitätsstraße 150

Building NC 2/74

D-44780 Bochum

Email:

Phone: +49 - (0)234 - 32 - 24150

http://www.ruhr-uni

Project Pluto+

The network project PluTO+ aims to increase the quality and yield of optical deposition technologies started in Octobre 2014. It has an overall volume of 9.5 billion Euro. The BMBF supports the project within the support programme "Photonik Forschung Deutschland". Project coordinator is Bühler Alzenau GmbH, more information can be found here.

Contact

Prof. Dr. Ralf Peter Brinkmann

Chair for Theoretical Electrical Engineering

Ruhr-Universität Bochum

Universitätsstr. 150

ID 1/127

44801 Bochum

Telephone: +49 (0)234 / 32 - 26336

Astrophysical Processes in the Heliospheric Environment

The BMBF promoted project "Astrophysical Processes in the Heliospheric Environment" is coordinated by the Ruhr-Universität Bochum. Project partners are Rheinische Friedrich-Wilhelms-Universität Bonn, Christian-Albrechts-Universität zu Kiel, Julius-Maximilians-Universität Würzburg as well as the Max-Planck-Institut für Sonnensystemforschung in Göttingen.

The transit time is from April 1st, 2015 up to March 31st, 2018.

Abstract: To enhance the understanding of the heliosphere and her surrounding as astrophysical system, the project includes the development, expansion, and refinement of theory and modelling of turbular (inter)stellar plasmas and the transport of energetic partlices in it.

Contact

PD Dr. Horst Fichtner

Ruhr-Universität Bochum

Theoretical Physics IV - Heliophysics

Universitätsstr. 150

NB 7/26

44801Bochum

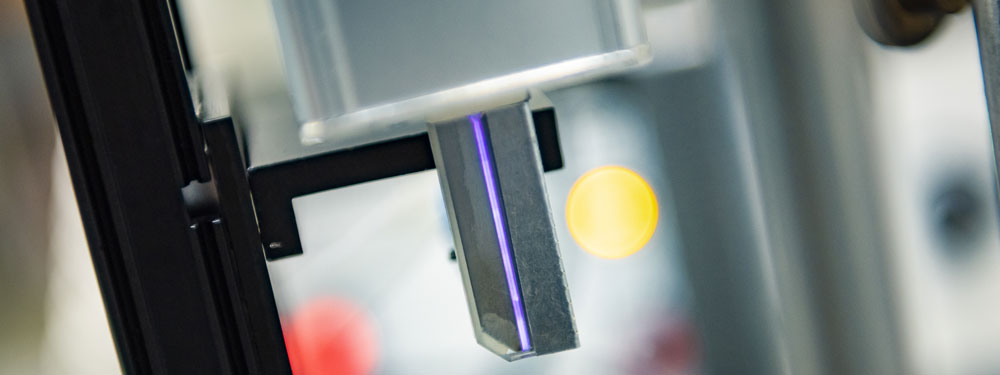

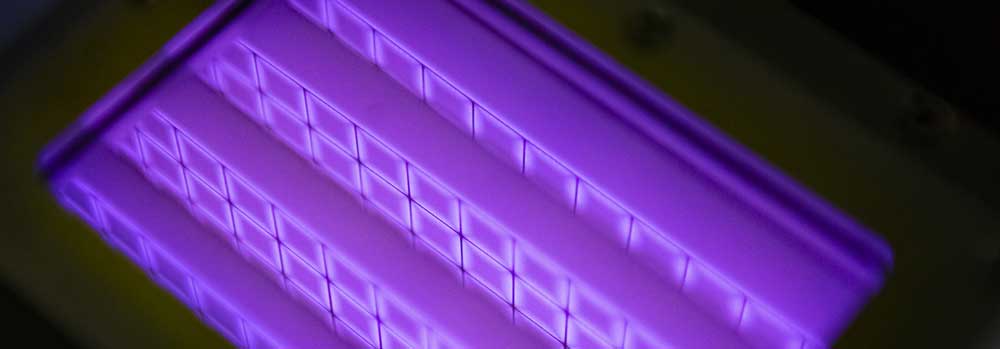

Plasma-based process control of reactive sputtering processes

Reactive sputtering processes in low-temperature plasmas are used for the deposition of thin films as the basis for many high-tech products. Despite this enormous social importance, fundamental mechanisms such as electron heating, plasma surface interactions and transport phenomena in these plasmas are not understood. Consequently, the non-linear and non-local influences of global parameters such as neutral gas pressure, gas flows, power, magnetic fields, etc. on the properties of the deposited thin films are not understood. This leads to massive limitations in process optimization and control. Lack of understanding and access to the actual layer-determining distribution functions of different species at the surfaces as well as the properties of these interfaces, existing process controls are based on the control of secondary variables such as gas flows and powers, which do not clearly determine the layer properties, as well as greybox models.

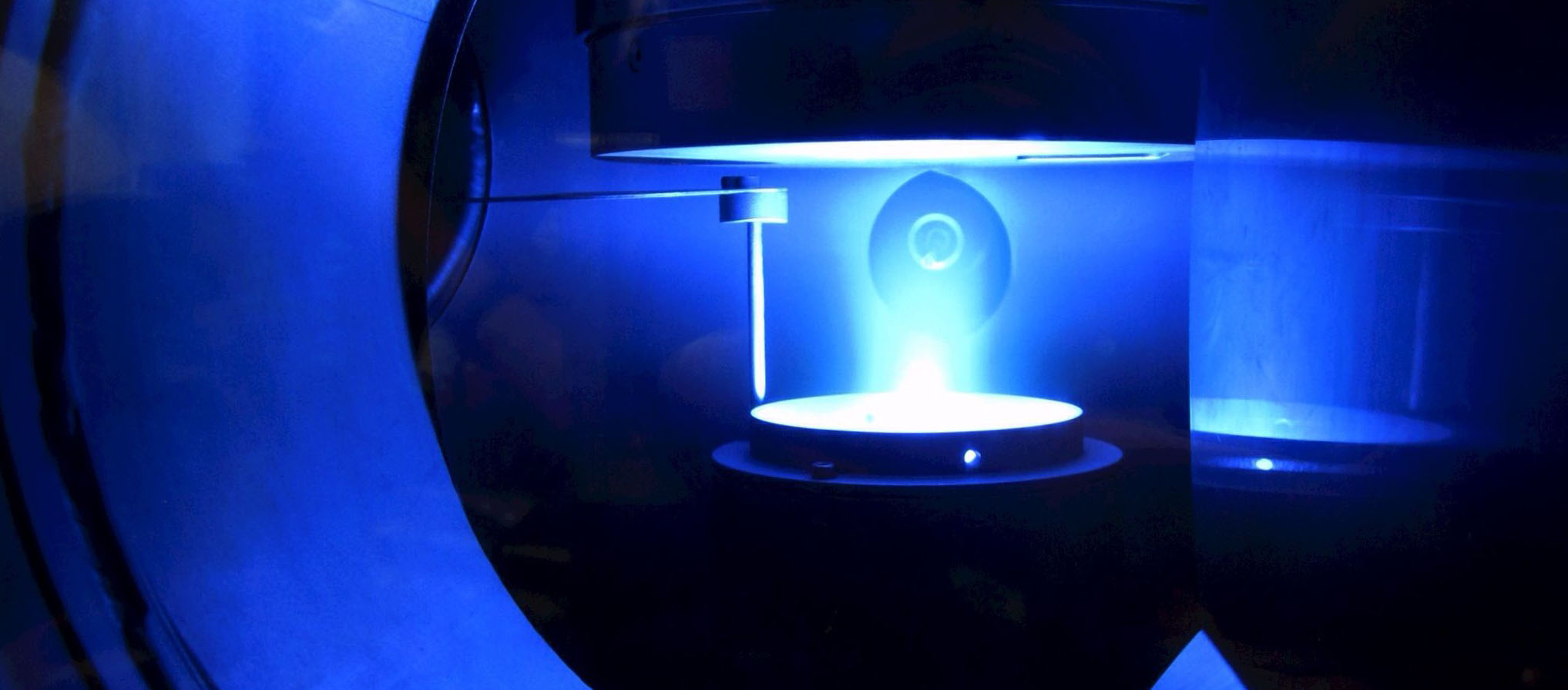

Thus, sputtering processes are representative for a multitude of plasma processes where similar problems exist. In this project, a plasma-based process control of reactive sputtering processes for the deposition of Al2O3 layers in a capacitive radio frequency (RF) magnetron, i.e. based on plasma sizes and scientific understanding, will be developed and tested for the first time. The first goal is to develop a fundamental understanding of the effect of global control variables on layer-determining distribution functions, surface and layer properties. For this purpose, a synergistic combination of experimental and theoretical methods will be used by characterizing the discharge numerically by a variety of plasma and surface diagnostics experimentally as well as by kinetic simulations. Based on this fundamental understanding, plasma quantities suitable for process control are to be determined, which can be measured non-invasively within seconds during the process and clearly correlate with the layer-determining distribution functions and surface properties.

These quantities are to be described by fast reduced global models, which make predictions about the causes and compensation measures of unwanted process drifts. The measured plasma quantities and models will then be used in a parallel developed control loop for process control, based on which a significantly improved control of thin film properties will be demonstrated. The aim is to make plasma properties such as the energy per incorporated particle adjustable in order to correlate the layer properties with the plasma properties and thus to be able to control layer properties. If successful, this concept of plasma-based process control can be transferred to other processes. In addition, important fundamental insights into the plasma physics of such discharges are expected.

The project is funding by the German Research Foundation (2018-2023). Project leaders are Prof. Brinkmann, Dr. habil. Julian Schulze, and Prof. Lunze from Ruhr-University Bochum.

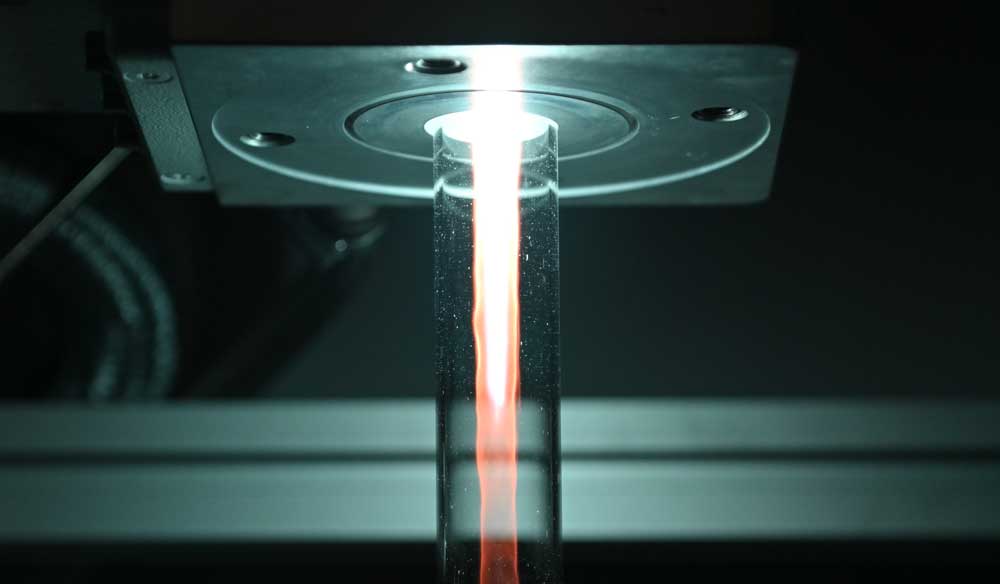

CAP-TBC

Mold temperature control and optimum parameterization of the process play a key role in the production of high-quality injection molded components. Inadequate temperature control of the mold walls can often result in surface defects such as gloss differences or weld line notches during the injection molding of molded parts. However, the use of dynamic temperature control techniques to minimize surface defects leads to significantly lower cost effectiveness, due to the additional energy added and the resulting longer cooling phase. The use of thermal barrier coatings slightly slows down the cooling process of the mold filling compound and thus makes extremely efficient use of the heat introduced into the plastic during the melting process. This makes it possible to increase the energy efficiency of the injection molding process without compromising part quality. Due to their low thermal conductivity and adapted coefficients of thermal expansion, oxide ceramic materials such as zirconia are the ideal materials for passive insulation layers. Within the scope of this project, innovative thermal insulation coatings and coating processes for injection molds are to be developed in an international project consortium. Significant improvements are to be made with regard to the achievable growth rates of the coatings

(>500 nm/h) as well as a reduction of the necessary layer thicknesses (<30 μm).

For this purpose, the application of functional coatings by metal organic chemical vapor deposition (MOCVD) is to be combined with plasma activation of the precursors. In this way, the advantages of conformal MOCVD layer formation with increased reactivity at low process temperatures, shorter process times and optimized porosity are to be achieved. With the envisaged development goals, effective process control and reproducible application of the coatings would be feasible for an industrial environment.

- link to Kunststoffinstitut Lüdenscheid

Project leader

Prof. Dr. Achim von Keudell

Experimental Physics II

Ruhr-Universität Bochum

Universitätsstraße 150

44801 Bochum

Tel.: +49 (0) 234 - 32 23680