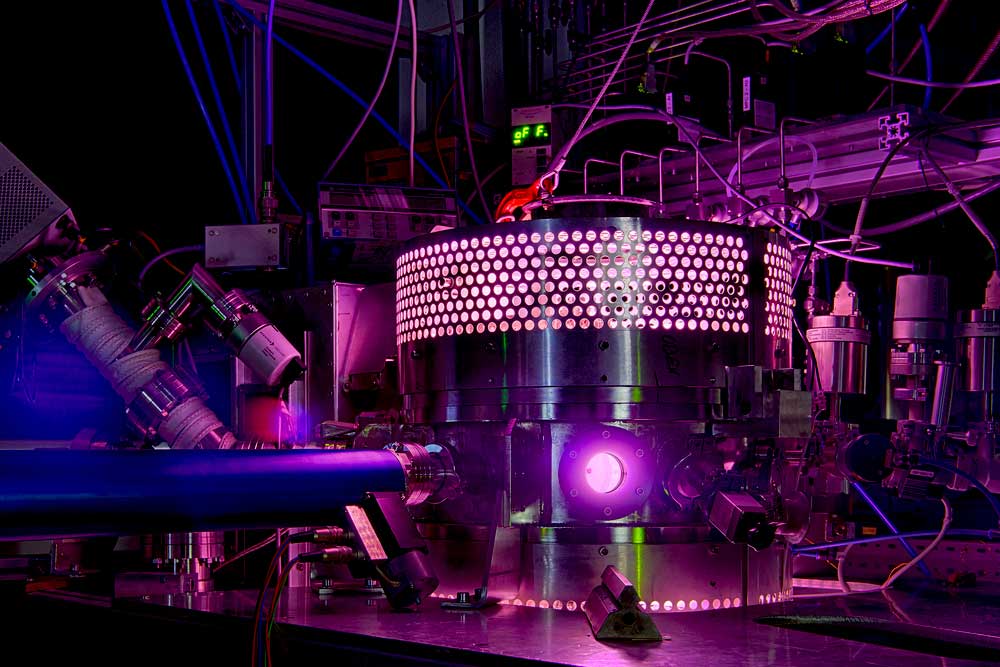

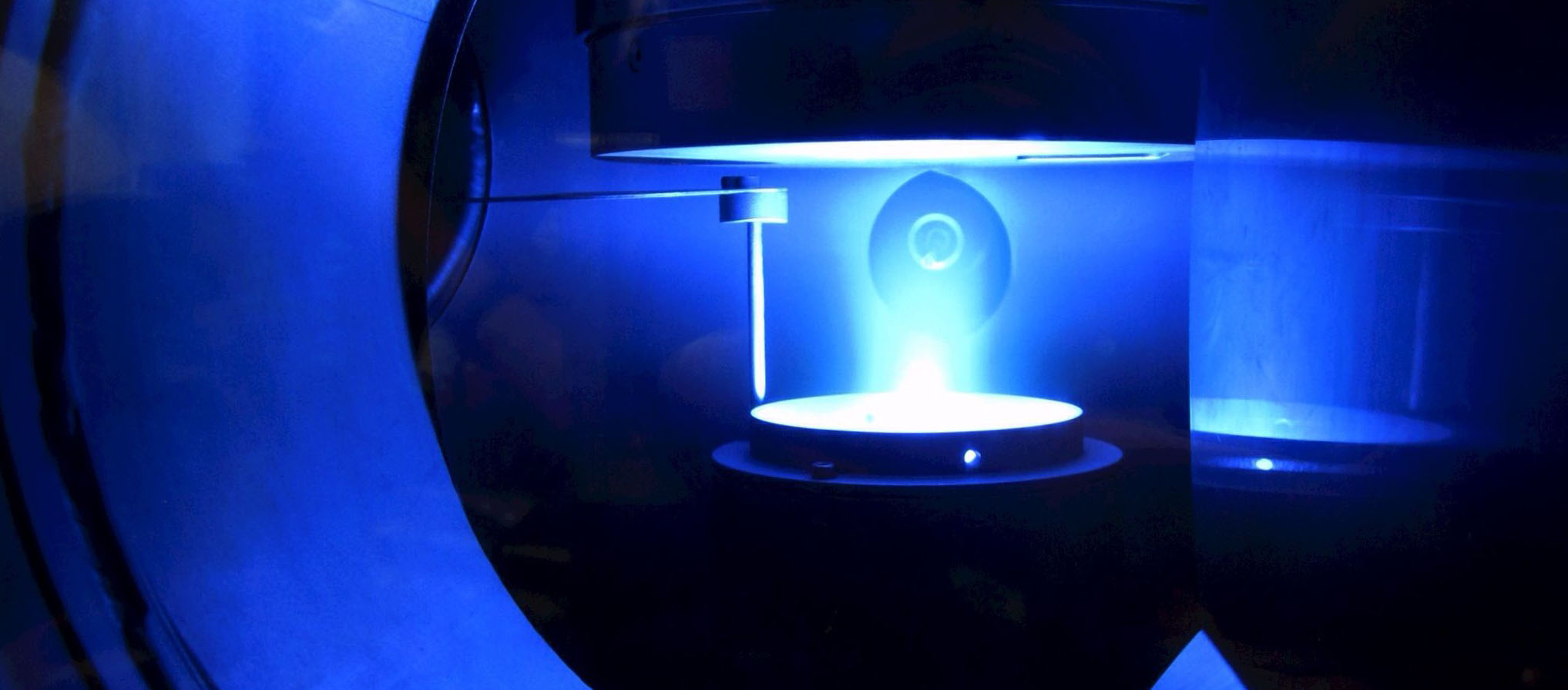

SFB-TR 87: Pulsed high power plasmas for the synthesis of nanostructured functional layers

Research Goal

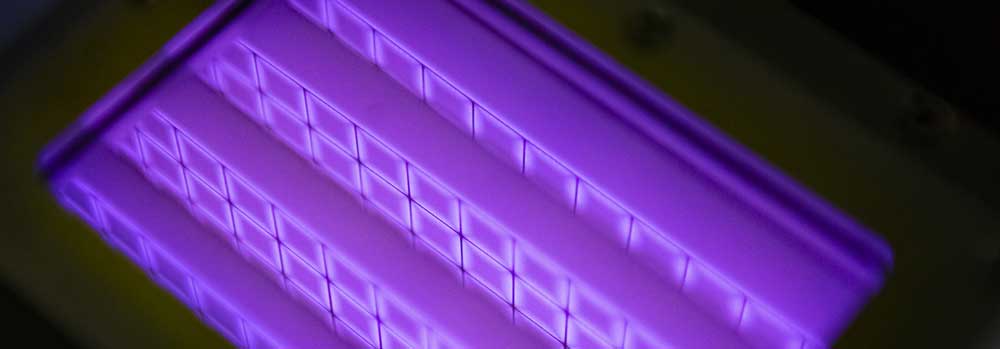

Structure widths of 50 nm and less, aspect ratios of 1:100 and more, the groundbreaking successes of Plasmaoberflächentechnik point the way for microelectronics and micro and nanostructure technology. The unique successes of this technology are based not least on new plasma source concepts, without which neither the speed nor the homogeneity and stability of the processes would have been possible. To this day, both the processes and the sources are constantly being further researched and developed, with the success that the storage capacity will become even larger, the mobile phones even smaller and the PCs even more powerful. Decisive for this success is the close integration of plasma diagnostics with process technology, in-situ control of process-relevant parameters and their correlation with the structures achieved.

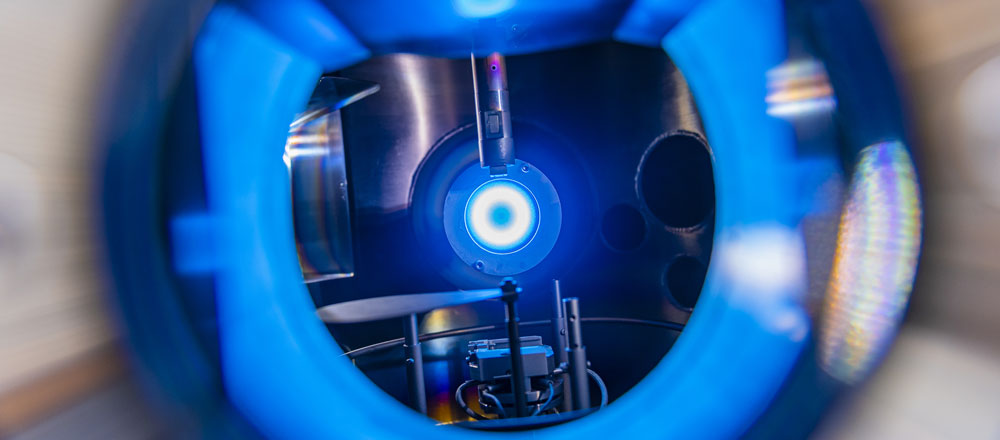

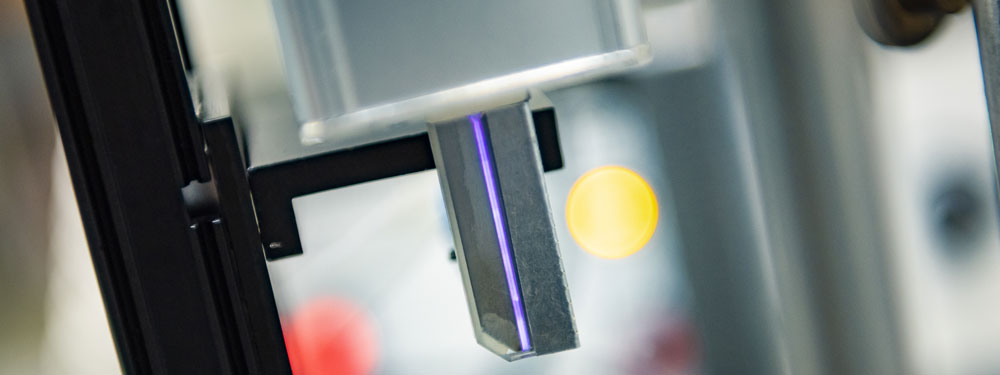

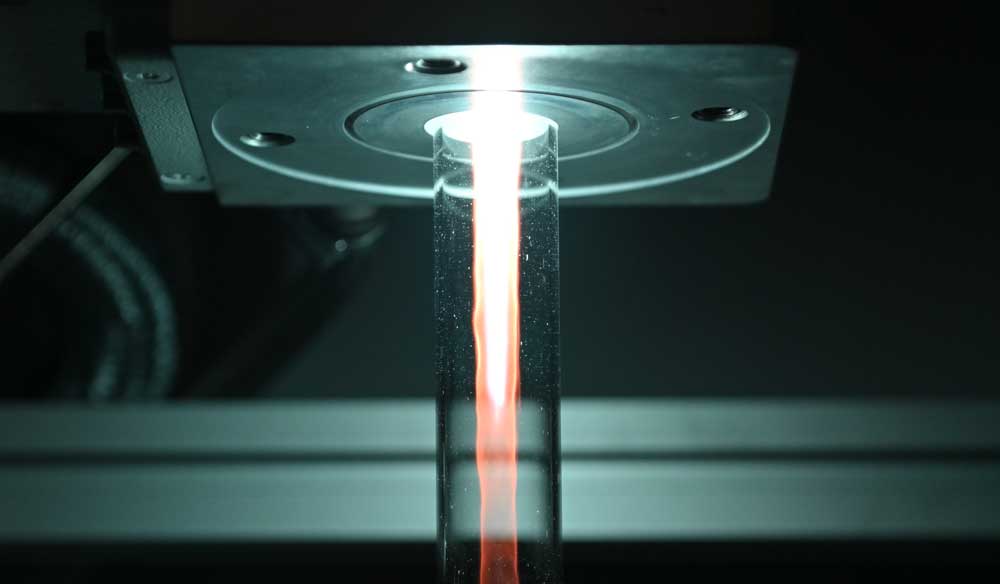

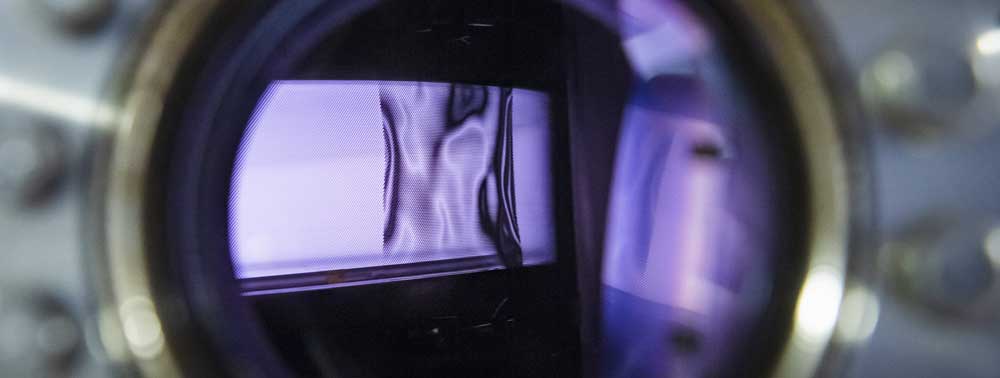

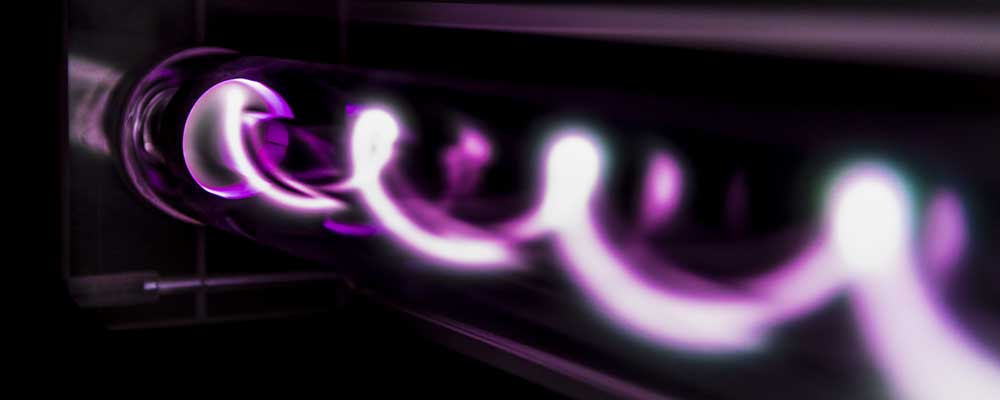

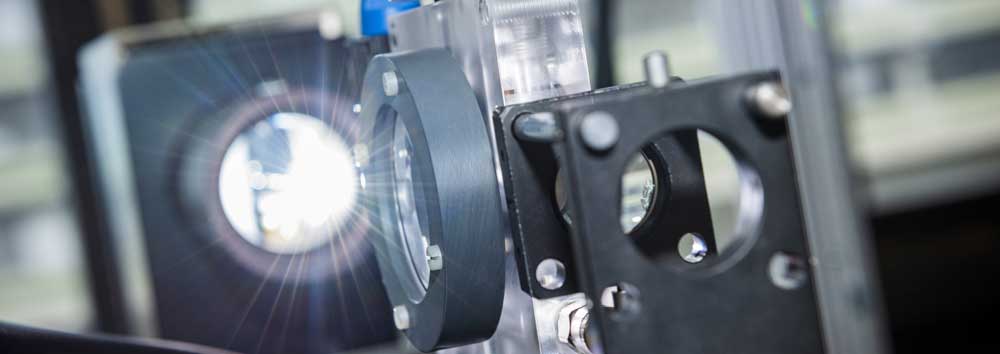

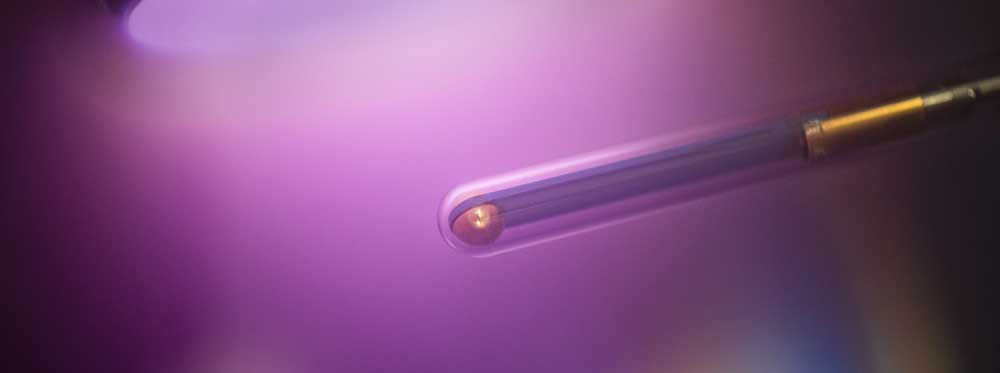

Today's coating techniques, both cathode sputtering processes and plasma-assisted gas-phase deposition, are similar to the plasma etching processes through new source concepts beflügelt. The common feature of the further development of both techniques is a significant increase in source powers up to the megawatt range as well as a pulsed power supply, which allows a targeted Beeinflussung of the plasma parameters while simultaneously controlling the thermal load of the materials. In this way, the plasmas used continue to be operated towards extreme non-equilibrium in order to deposit new metastable high-performance coatings for tribological applications in mechanical engineering. These coating materials are not only unique in terms of their chemical composition. Their nanostructured structure can also only be produced using the latest methods of plasma technology.

The aim of the SFB-TR 87 is to investigate coating systems with unique tribological properties on metal substrates and barrier properties on plastic substrates by bundling the expertise of two sites in the fields of plasma physics/plasma technology and materials science. For this purpose, the latest, partly self-developed source technology is used and characterized by a very broad spectrum of quantitative, partly newly developed plasma diagnostics, supported by modelling and unique single particle experiments. The aim is also to investigate the relationships between material properties and plasma parameters and to use them for plasma control, layer development and in-situ layer control. In this way, the empirical approach prevailing so far is overcome and a physically and chemically based process understanding is developed.

Further information

- Website SBF TR 87 http://www.sfbtr87.de/

Spokesperson

Prof. Dr.-Ing. Peter Awakowicz

Lehrstuhl für Allgemeine Elektrotechnik und Plasmatechnik

Fakultät für Elektrotechnik und Informationstechnik

Ruhr-Universität Bochum

Universitätsstraße 150

44801 Bochum

Tel.: +49 (0) 234 - 32 22487, 23062 Sekretariat

Fax: +49 (0) 234 - 32 14230

Deputy Spokesperson

Prof. Jochen M. Schneider, Ph.D.

Lehrstuhl für Werkstoffchemie

Fakultät Georessources und Materialtechnik

Rheinisch-Westfälische Technische Hochschule Aachen

Kopernikusstraße 10

52056 Aachen

Tel.: +49 (0) 241 - 80 25 966

Fax: +49 (0) 241 - 80 22 295