Plasma-based process control of reactive sputtering processes

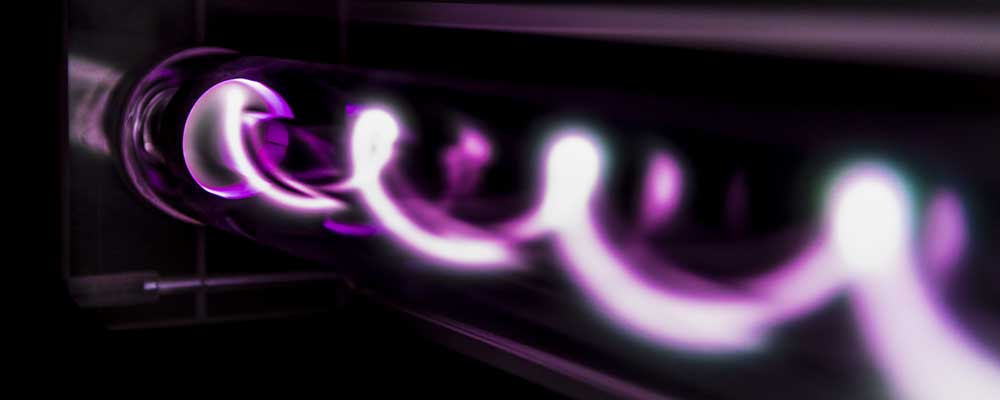

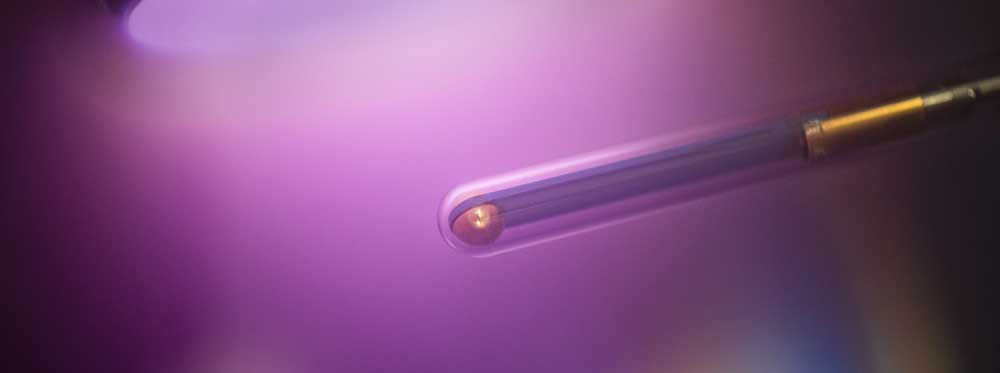

Reactive sputtering processes in low-temperature plasmas are used for the deposition of thin films as the basis for many high-tech products. Despite this enormous social importance, fundamental mechanisms such as electron heating, plasma surface interactions and transport phenomena in these plasmas are not understood. Consequently, the non-linear and non-local influences of global parameters such as neutral gas pressure, gas flows, power, magnetic fields, etc. on the properties of the deposited thin films are not understood. This leads to massive limitations in process optimization and control. Lack of understanding and access to the actual layer-determining distribution functions of different species at the surfaces as well as the properties of these interfaces, existing process controls are based on the control of secondary variables such as gas flows and powers, which do not clearly determine the layer properties, as well as greybox models.

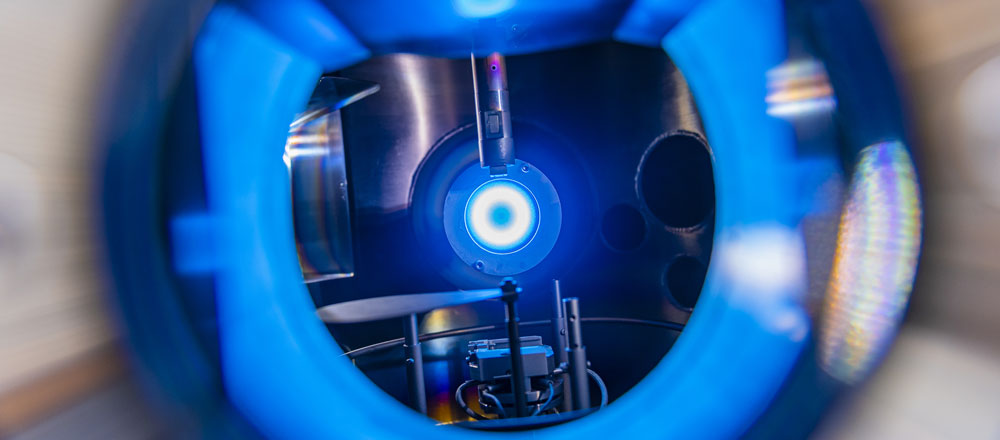

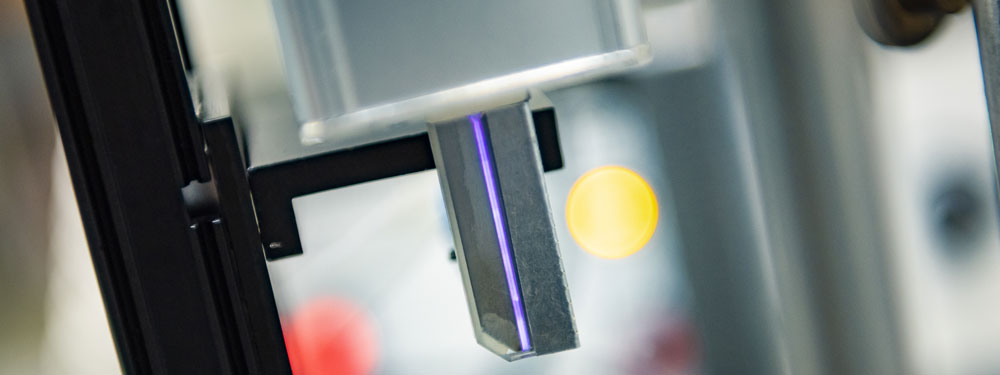

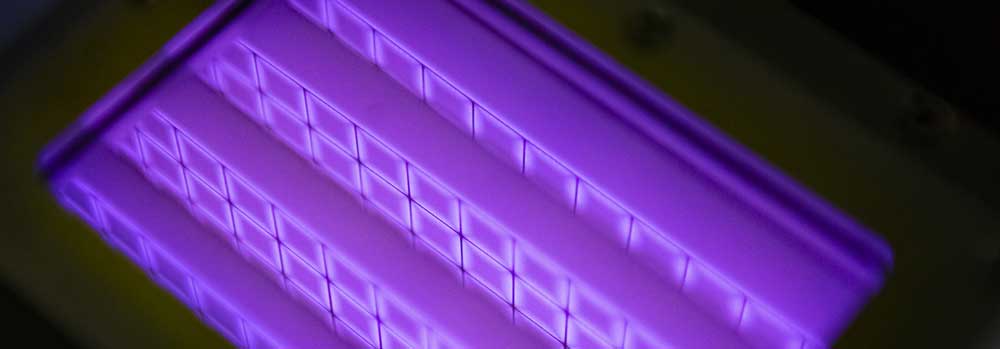

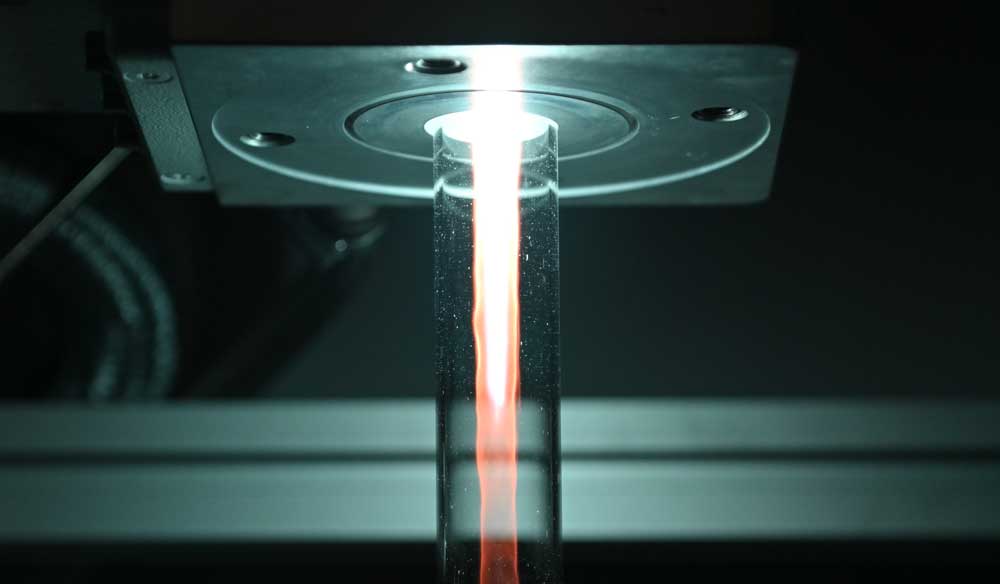

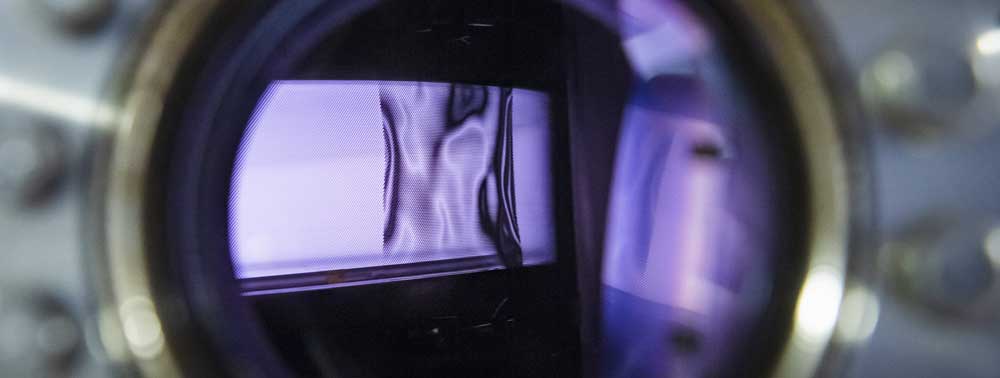

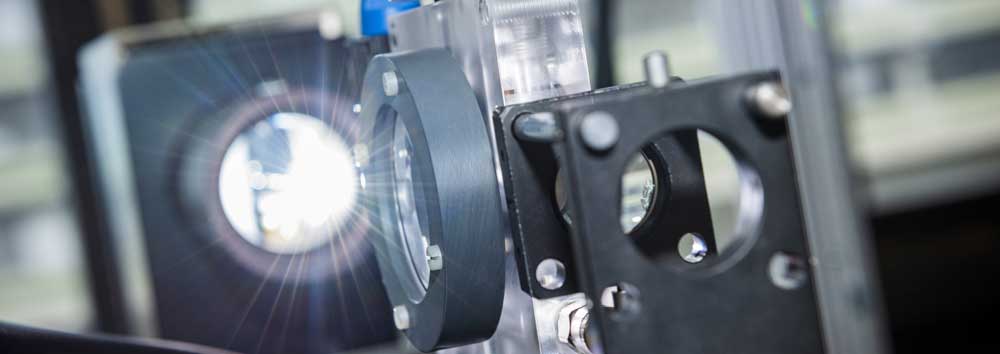

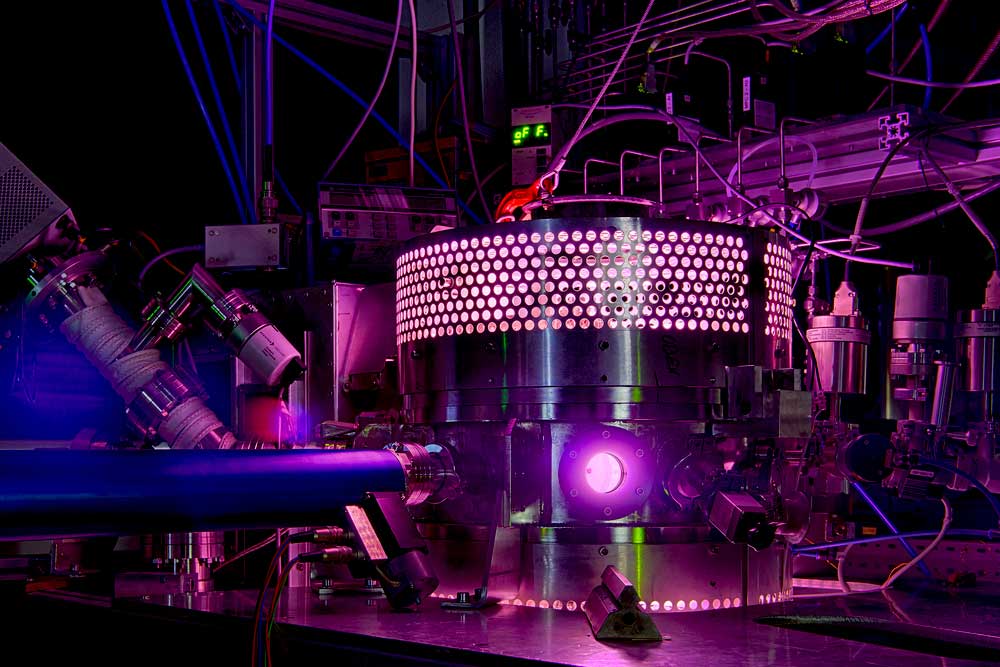

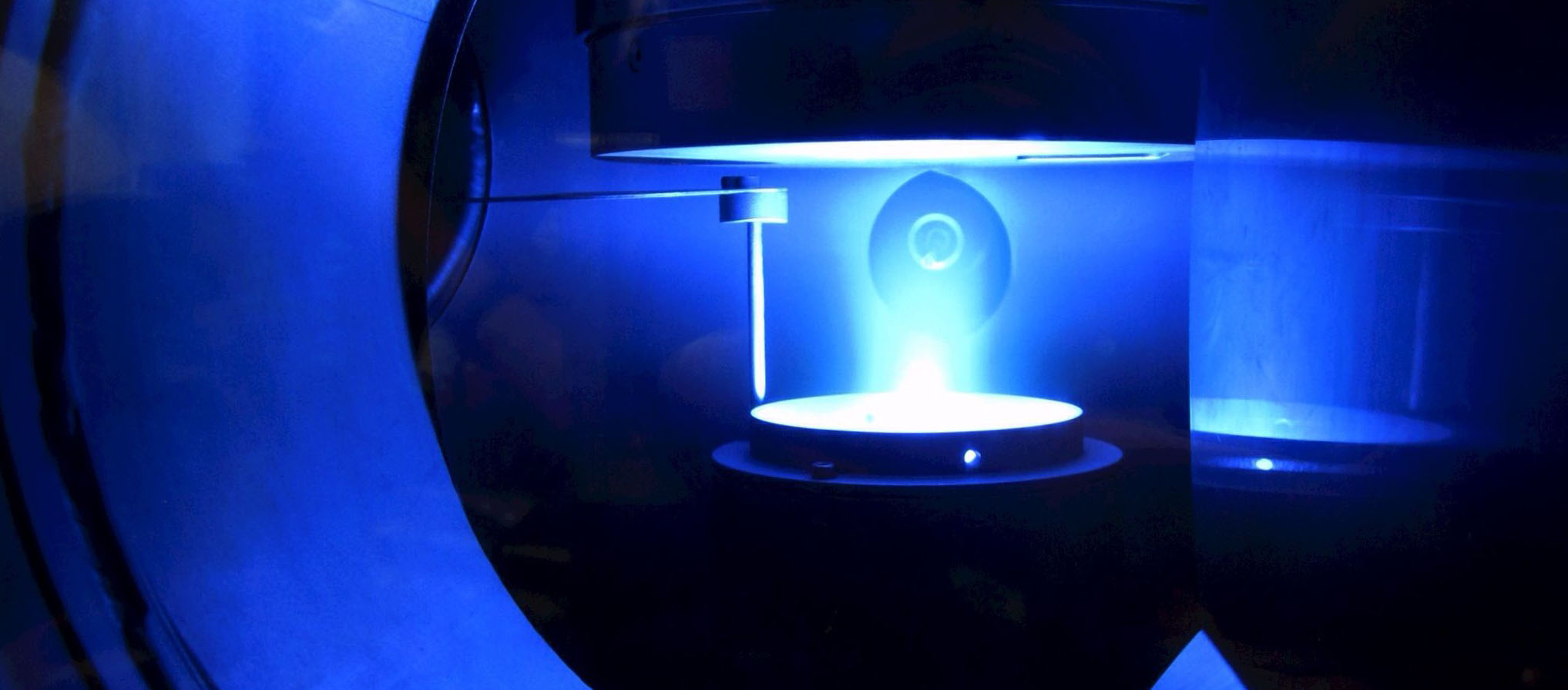

Thus, sputtering processes are representative for a multitude of plasma processes where similar problems exist. In this project, a plasma-based process control of reactive sputtering processes for the deposition of Al2O3 layers in a capacitive radio frequency (RF) magnetron, i.e. based on plasma sizes and scientific understanding, will be developed and tested for the first time. The first goal is to develop a fundamental understanding of the effect of global control variables on layer-determining distribution functions, surface and layer properties. For this purpose, a synergistic combination of experimental and theoretical methods will be used by characterizing the discharge numerically by a variety of plasma and surface diagnostics experimentally as well as by kinetic simulations. Based on this fundamental understanding, plasma quantities suitable for process control are to be determined, which can be measured non-invasively within seconds during the process and clearly correlate with the layer-determining distribution functions and surface properties.

These quantities are to be described by fast reduced global models, which make predictions about the causes and compensation measures of unwanted process drifts. The measured plasma quantities and models will then be used in a parallel developed control loop for process control, based on which a significantly improved control of thin film properties will be demonstrated. The aim is to make plasma properties such as the energy per incorporated particle adjustable in order to correlate the layer properties with the plasma properties and thus to be able to control layer properties. If successful, this concept of plasma-based process control can be transferred to other processes. In addition, important fundamental insights into the plasma physics of such discharges are expected.

The project is funding by the German Research Foundation (2018-2023). Project leaders are Prof. Brinkmann, Dr. habil. Julian Schulze, and Prof. Lunze from Ruhr-University Bochum.