- Details

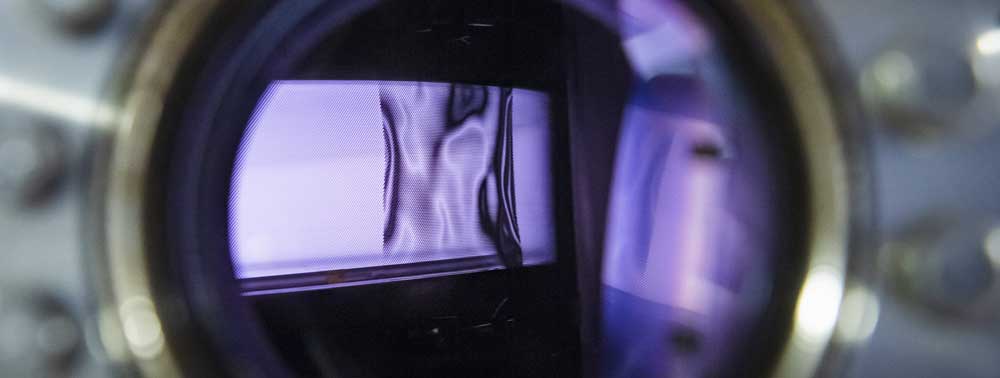

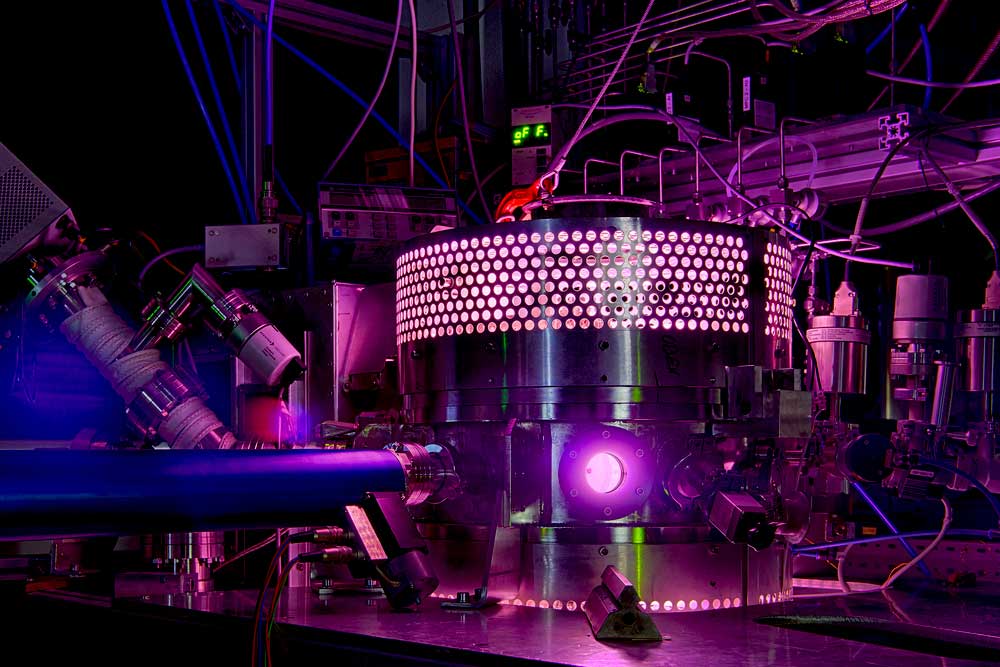

Several contributions on the International Conference on Phenomena in Ionized Gases (ICPIG)

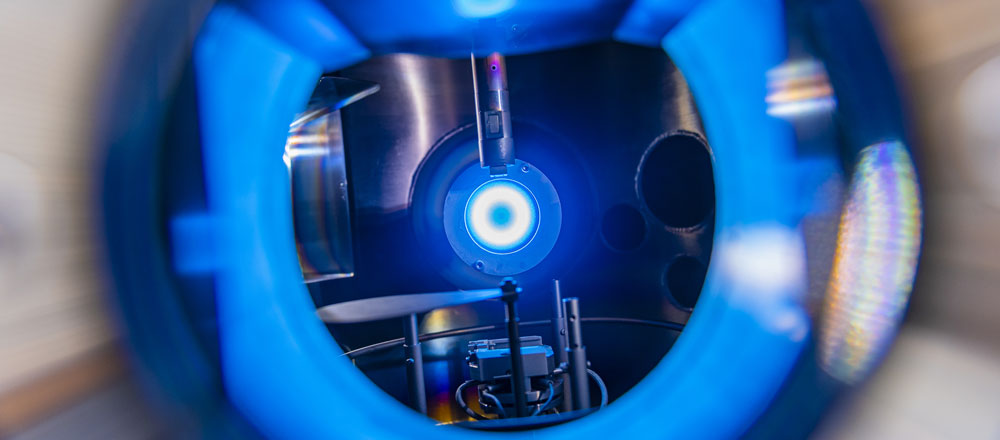

In July, the scientific work of the CRC 1316 has been presented in four talks and several posters in Aix en Provence during the ICPIG conference. At this conference, various fields within plasma physics are joined: Modelling and experiments, from fundamental research to applications. CRC Members from the physics, chemistry and engineering department contributed to the fruitful scientific exchange. One highlight was an excursion to the ITER site; the large research reactor for fusion, currently being built in Cadarache.

In July, the scientific work of the CRC 1316 has been presented in four talks and several posters in Aix en Provence during the ICPIG conference. At this conference, various fields within plasma physics are joined: Modelling and experiments, from fundamental research to applications. CRC Members from the physics, chemistry and engineering department contributed to the fruitful scientific exchange. One highlight was an excursion to the ITER site; the large research reactor for fusion, currently being built in Cadarache.

- Details

Premiere of the SFB1491 Planetarium Show

We are pleased to announce that the SFB1491 planetarium show Unser exotisches Universum will premiere on October 8, 2025, as part of the 10th anniversary ceremony of the RAPP Center.

The production offers audiences a unique glimpse into the wide-ranging research conducted within our CRC:

Combining cutting-edge scientific insights with visually stunning projections, the show takes viewers on a journey through the exciting world of modern physics and astrophysics — from experiments at the Large Hadron Collider (LHC) and cosmic rays in the Milky Way and other galaxies to stellar explosions and active galactic nuclei (AGNs).

Please note that the show is currently available in German only. An English version is in preparation.

Beginning October 12, the show will be presented regularly at the Planetarium Bochum and at other venues, including the LWL-Museum für Naturkunde mit Planetarium and Planetarium Mannheim .

Further information on the detailed schedule at the Planetarium Bochum can be found here.

Please also have a look at the RUB's News article on our show here.

https://www.youtube.com/watch?v=FmYDtF8V4OM?si=qsycfGYqsZnERfWR

- Details

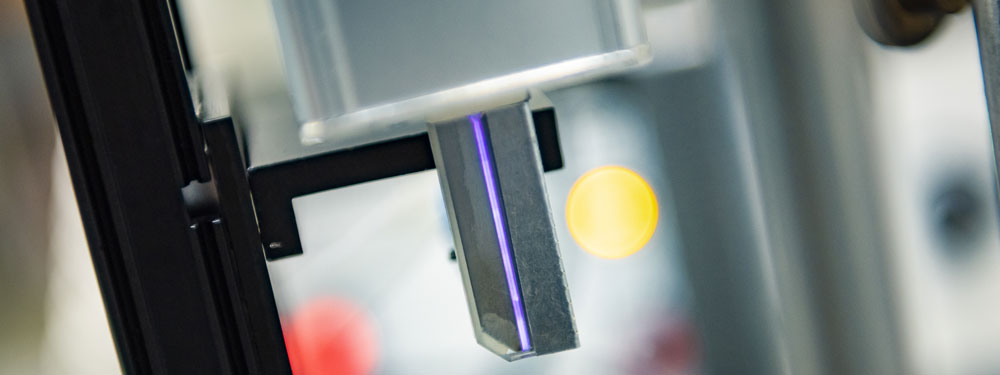

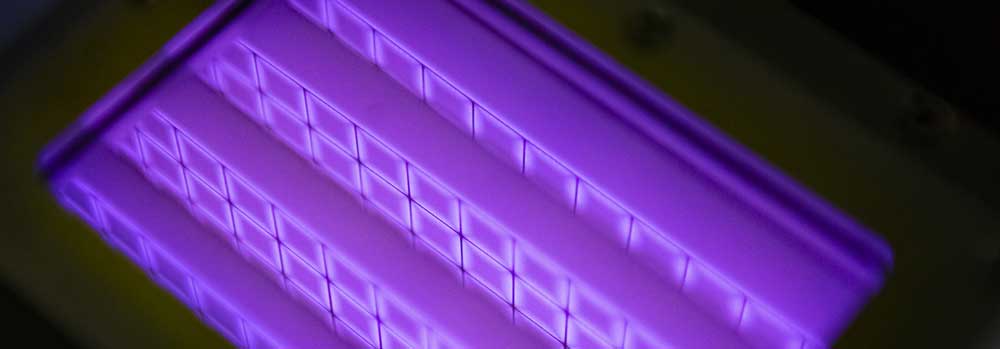

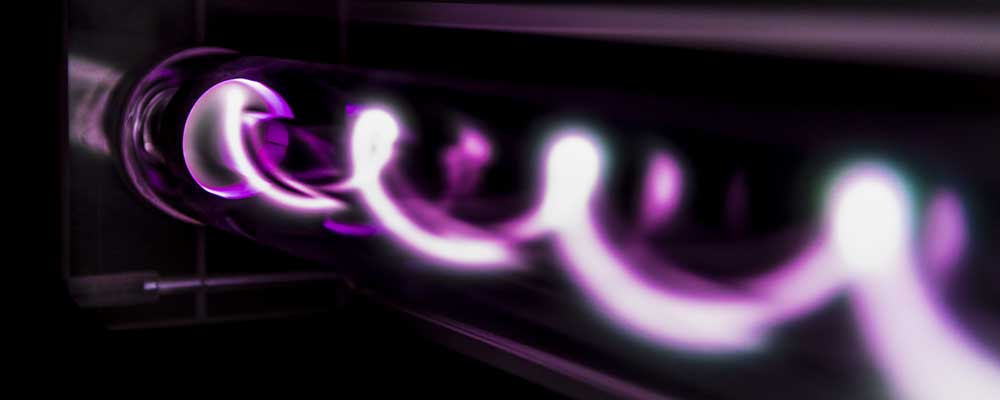

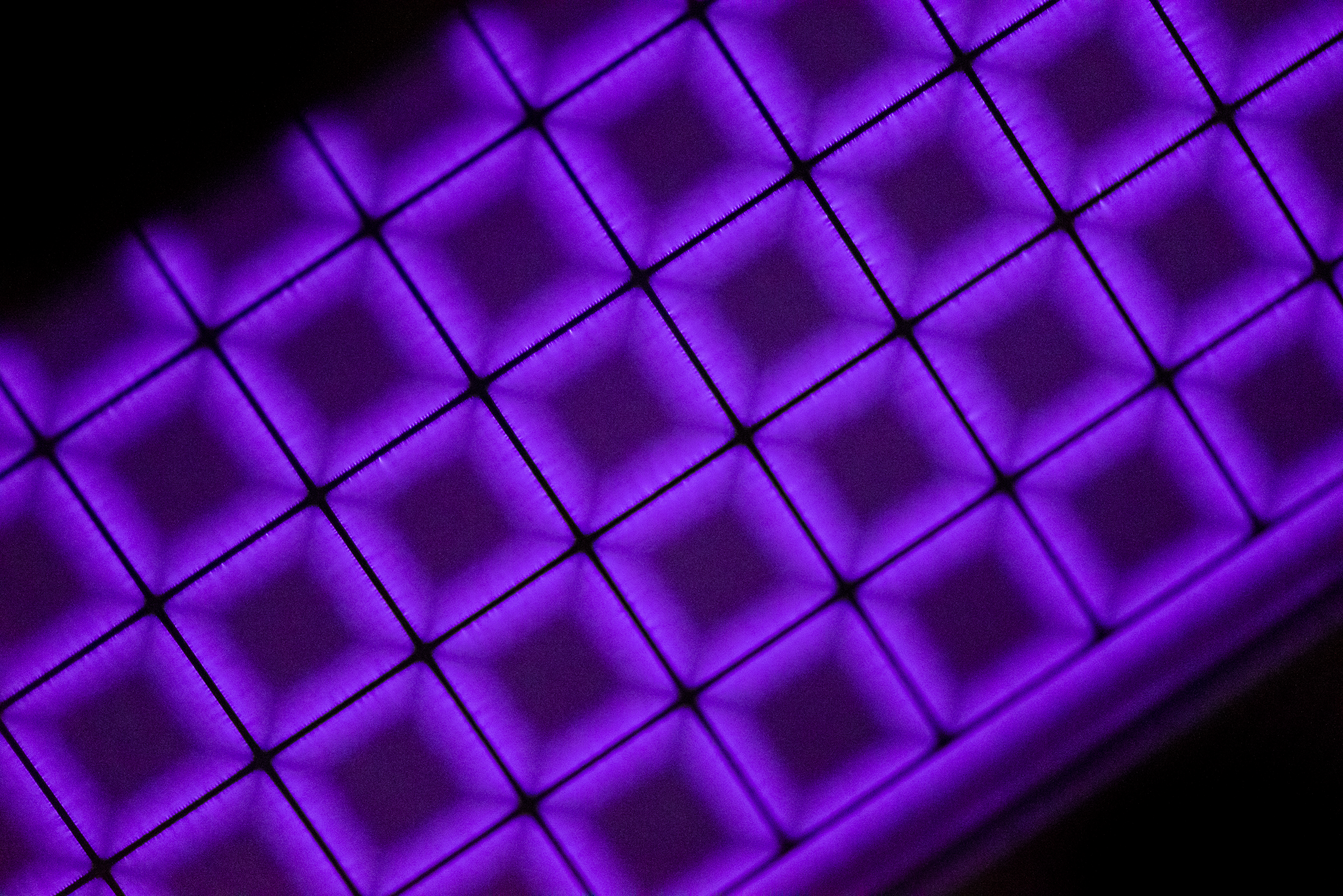

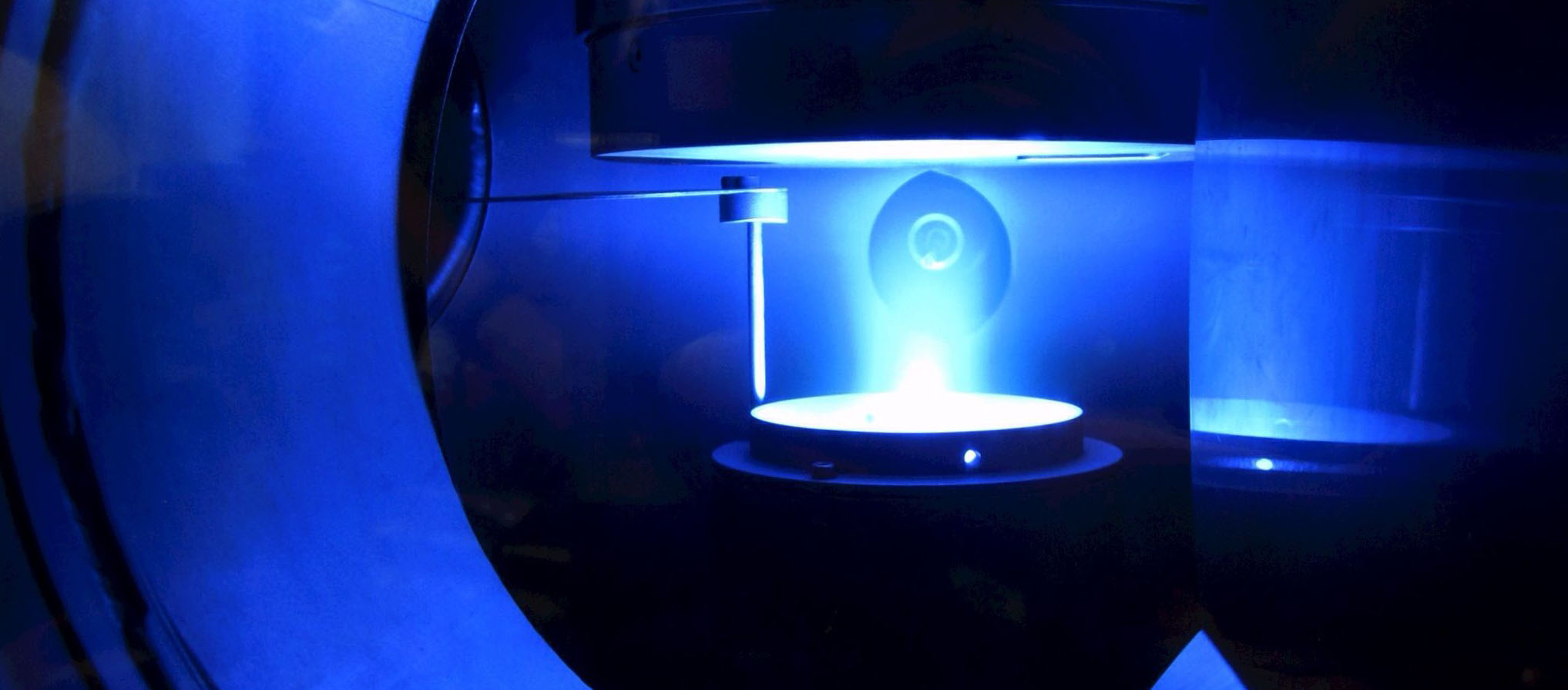

Plasma experiments with the mouse

On 3th October, we celebrated the nationwide Mouse Day.

On 3th October, we celebrated the nationwide Mouse Day.

The Faculty of Physics at Ruhr-University Bochum invited children to discover the exciting world of physics and try their hand at lots of experiments.

In our workshop, the children were able to explore the glow of plasma and its applications. As a souvenir, the Mouse fans coated small ducks with gold using plasma.

- Details

Splinter Meeting at the German Astronomical Society Annual Meeting 2025

The CRC 1491 contributed to the 2025 Annual Meeting of the German Astronomical Society (Astronomische Gesellschaft) with the dedicated Splinter Session “Multi-messenger Signatures of Feedback Processes in Galaxies”, organized by Dominik Bomans and Dominik Elsässer.

The CRC 1491 contributed to the 2025 Annual Meeting of the German Astronomical Society (Astronomische Gesellschaft) with the dedicated Splinter Session “Multi-messenger Signatures of Feedback Processes in Galaxies”, organized by Dominik Bomans and Dominik Elsässer.

This session brought together experts to discuss recent advances in understanding feedback mechanisms in galaxies through multi-messenger and multi-wavelength observations. The presentations and discussions explored how active galactic nuclei, massive stars, cosmic rays, and magnetic fields shape the interstellar medium, drive turbulence, and influence cosmic ray transport.

The full program can be found here.

- Details

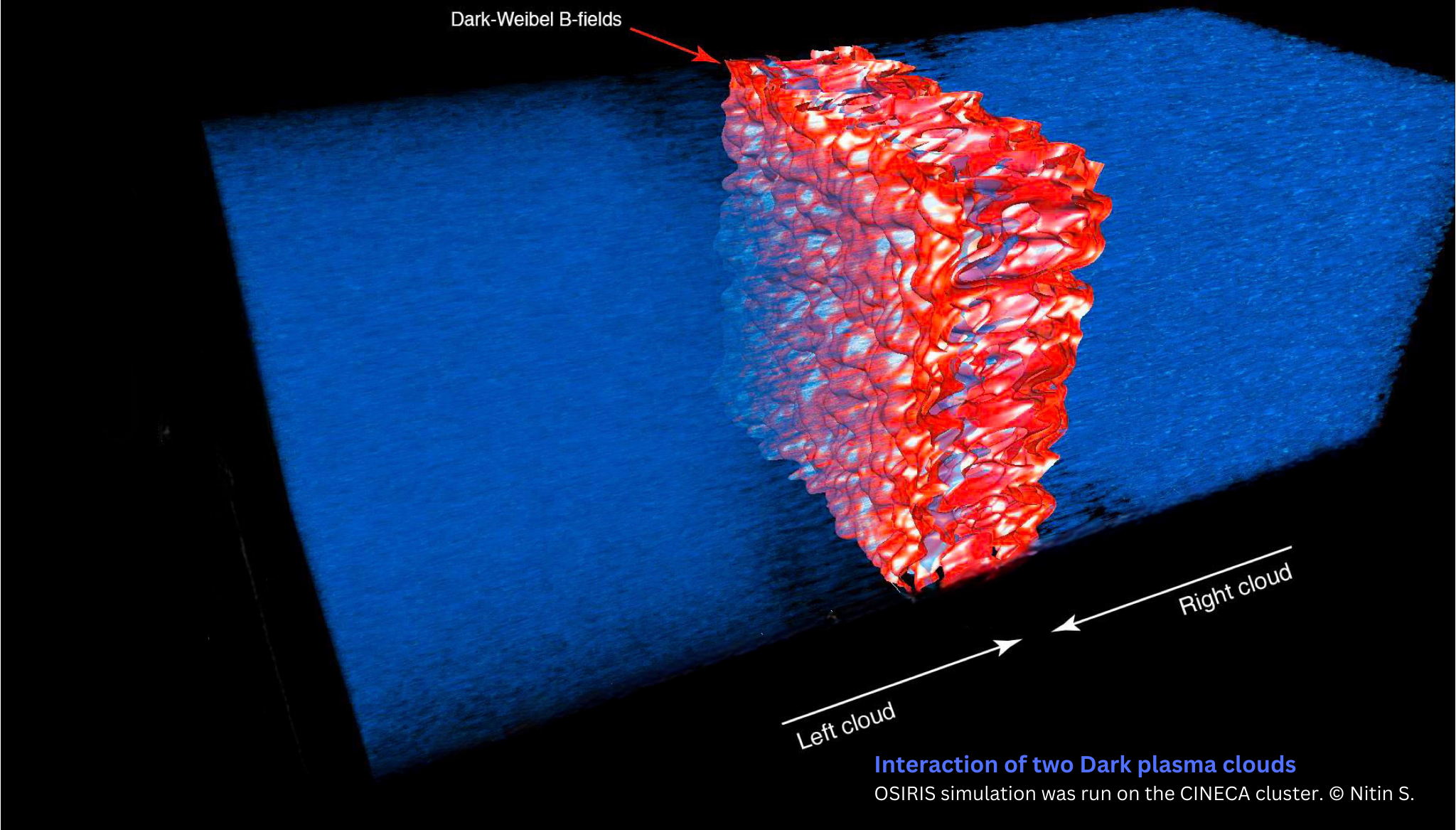

Exciting News in Plasma Physics and Dark Matter Research

A recent study by the scientist Kevin Schoeffler, together with his colleagues Nitin Shukla (CINECA High-Performance Computing Department, Italy), and Luis Silva (Universidade de Lisboa, Portugal), has set a strong upper bound on long-range dark matter interactions through plasma physics. The research explores the intriguing possibility that dark matter could be charged under a unique “dark electromagnetism” (dark-EM), causing it to behave like a cold collisionless plasma.

Using advanced simulations, the team discovered that plasma instabilities could lead to significant slowdowns in dark matter dynamics.

Interestingly, astronomical observations of colliding galaxy clusters like the so-called „Bullet Cluster“ only fits to their findings if the interaction strength is extremely weak. As a result, they established a strong upper bound on the dark electromagnetic self-interaction constant.

This new constraint is much stronger than previous limits, suggesting that dark electromagnetic interactions are highly restricted.

This research not only advances our understanding of dark matter but also opens new avenues for further exploration and verification through observational measurements.

Read the full article here:

Can plasma physics establish a significant bound on long-range dark matter interactions?

K. Schoeffler N. Shukla and L. O. Silva, Phys. Rev. D 111, L071701

And please have a look at the popular science article here:

Intergalactic Collision Constrains Dark Electromagnetism

Physics 18, s48

Picture: Counterstreaming slabs of dark matter plasma, shown in blue, are slowed down while interacting with dark magnetic fields, shown in red, which are generated by kinetic plasma instabilities.

- Details

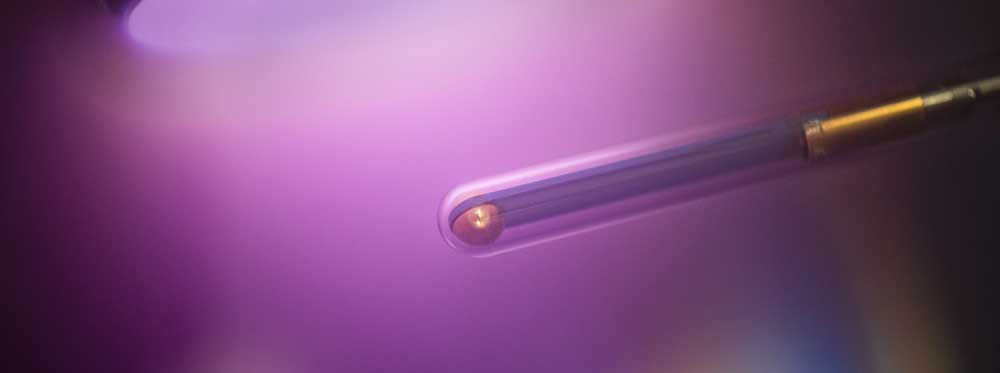

Lab visit in Brazil

From Bochum to Brazil! Sarah Thiel set off on her journey and spent an exciting exchange semester at the Universidade Federal de São Carlos (UFSCar) in Brazil. Sarah is studying for a master's degree in biology at the RUB and is conducting research on enzyme immobilization in a project run by SFB1316. In Brazil, she continued working on her research project and learned new methods. But outside of research, Sarah also learned what it's like to live alone in a completely foreign country – with a new language, new people, and a completely different culture. In addition to new friendships, she brings back great impressions of everyday life in Brazil and unique experiences.

The stay took place as part of the Research School's Visiting International Professor Program, which is made possible by a cooperation between RUB and UFSCar. The research stay was funded by SFB1316.

- Details

CRC annual meeting in Hamminkeln

Building on the success of last year, this year’s general assembly of CRC 1316 once again took place in Hamminkeln-Dingden.

Building on the success of last year, this year’s general assembly of CRC 1316 once again took place in Hamminkeln-Dingden.

Over the course of three days, the CRC 1316 members discussed recent results and especially focussed on the upcoming scientific work.

The overwhelmingly positive feedback highlights the importance of this annual gathering in fostering scientific dialogue and advancing collaborative research.

- Details

Sam Taziaux selected for CSIRO Student Program!

The CSIRO Student Program is a competitive initiative by the CSIRO, Australia’s national science agency. The program supports a small number of early-career researchers whose work aligns closely with CSIRO’s scientific priorities and who actively contribute to collaborative research with CSIRO teams.

The CSIRO Student Program is a competitive initiative by the CSIRO, Australia’s national science agency. The program supports a small number of early-career researchers whose work aligns closely with CSIRO’s scientific priorities and who actively contribute to collaborative research with CSIRO teams.

Within project A2 of the CRC 1491, Sam focuses on the role of magnetic fields in dwarf galaxies and the transport of cosmic rays.

As part of the CSIRO Student program, Sam will return to Perth in November 2025 for a one-month research visit, deepening the scientific collaboration and highlighting the growing ties between the SFB and CSIRO.

He will work directly with Tim Galvin, Alec Thomson, and George Heald on joint modeling approaches and data interpretation, laying the groundwork for future shared initiatives.

- Details

Julia Tjus Member of the DFG Senate

The Senate is the central scientific body that advises on all matters of fundamental importance to the DFG and, in many cases, also makes decisions.

- Details

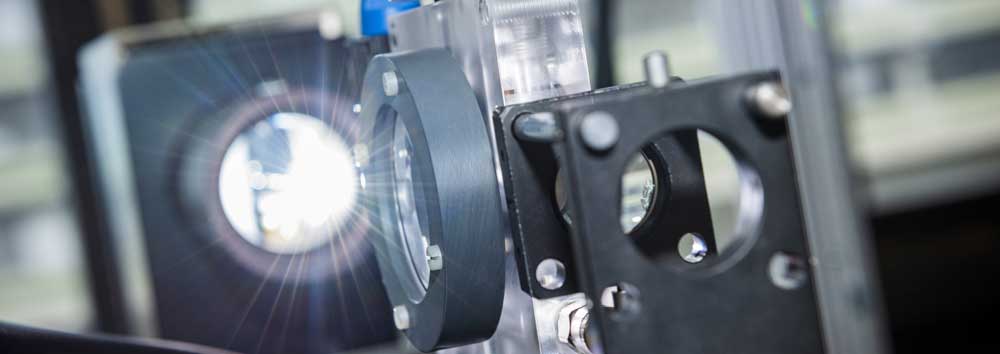

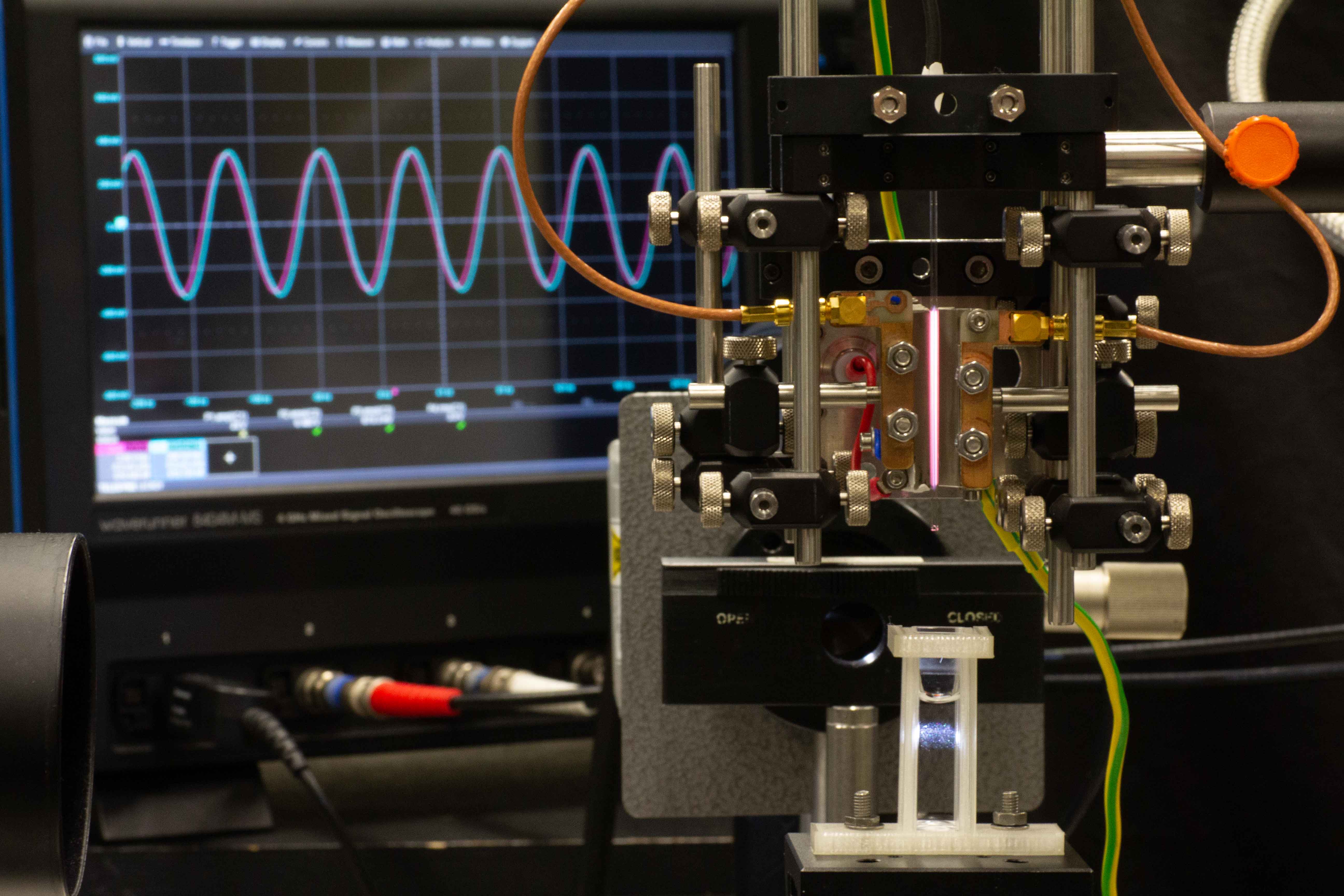

CRC1316 presents at ISPC 26

Seven researchers from the CRC1316 presented their results at the international symposium on plasma chemistry ISPC 26 in Minneapolis 15.6.-20.6.2025. The contributions included one invited lecture, 4 oral presentations, and one poster. The conference offered the possibility to interact with the peers in the community and to exchange new ideas and identify new trends.

Seven researchers from the CRC1316 presented their results at the international symposium on plasma chemistry ISPC 26 in Minneapolis 15.6.-20.6.2025. The contributions included one invited lecture, 4 oral presentations, and one poster. The conference offered the possibility to interact with the peers in the community and to exchange new ideas and identify new trends.

- Details

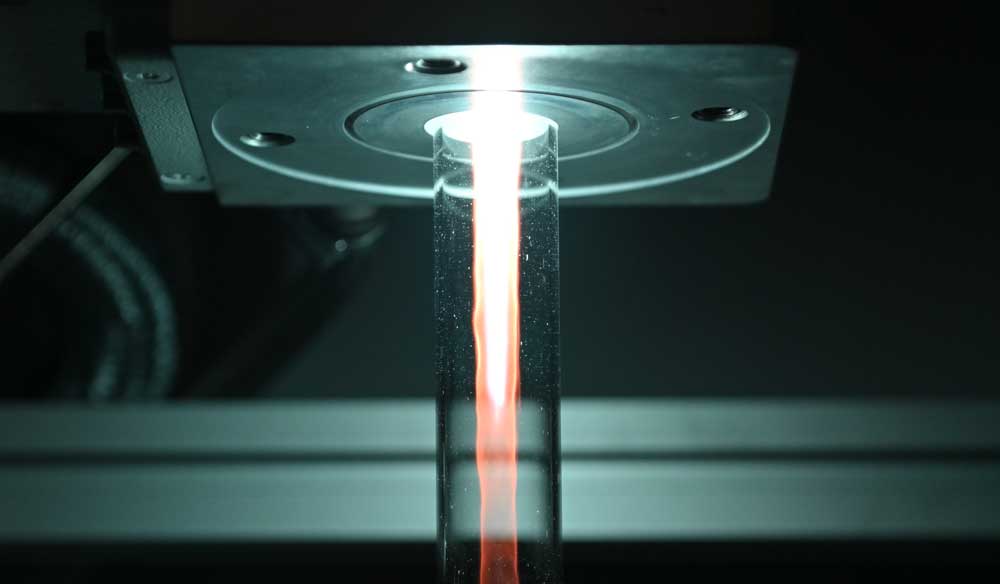

Public lecture „Die Geburt stellarer Monster - Über die Entstehung der massereichsten Sterne im Universum“

We are pleased to invite you to the public lecture “Die Geburt stellarer Monster - Über die Entstehung der massereichsten Sterne im Universum " (in German).

We are pleased to invite you to the public lecture “Die Geburt stellarer Monster - Über die Entstehung der massereichsten Sterne im Universum " (in German).

In his talk, Rolf Kuiper will explore how the most massive stars in the cosmos are formed, which are rare in number, but extremely bright. He will connect the latest insights from astrophysical simulations with brand-new observations of young, massive star-forming regions that have only recently become accessible.

When 25.6.25 at 20:00

Where Planetarium Bochum

For registration and further information, please have a look at the Planetarium’s homepage.

Picture:

In the S 106 region, about 2,000 light-years from Earth, a particularly massive star is being born.